Design Strategy

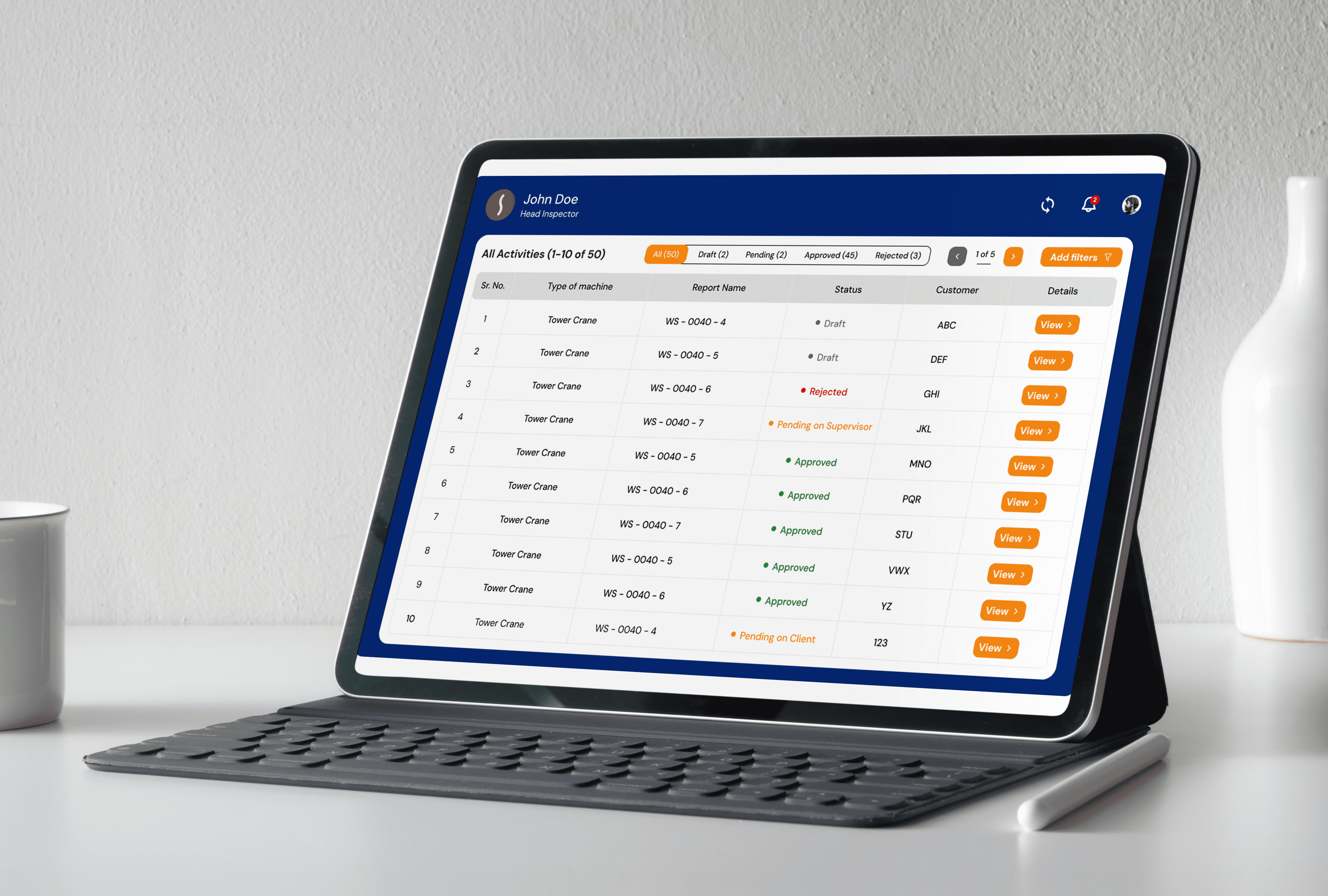

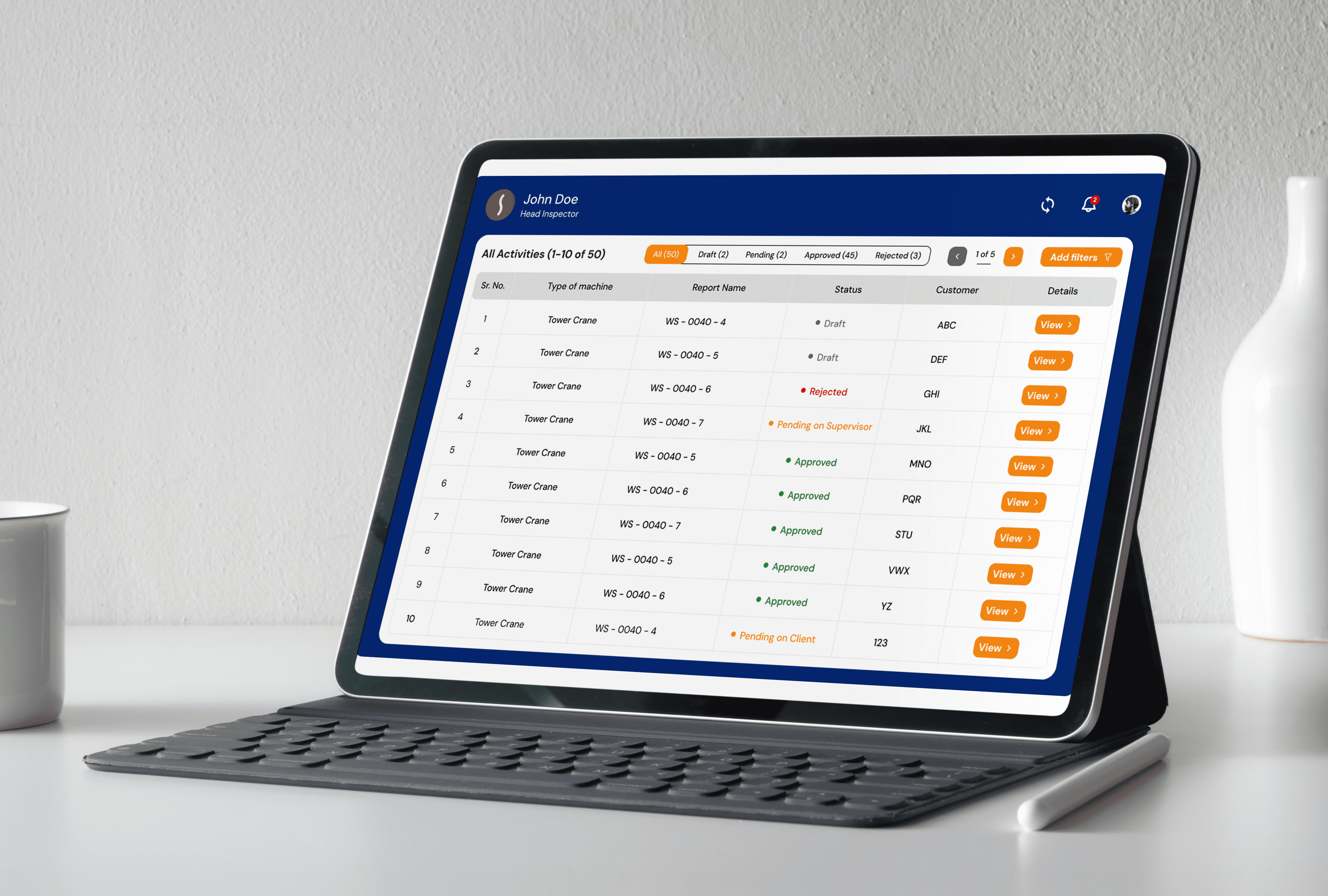

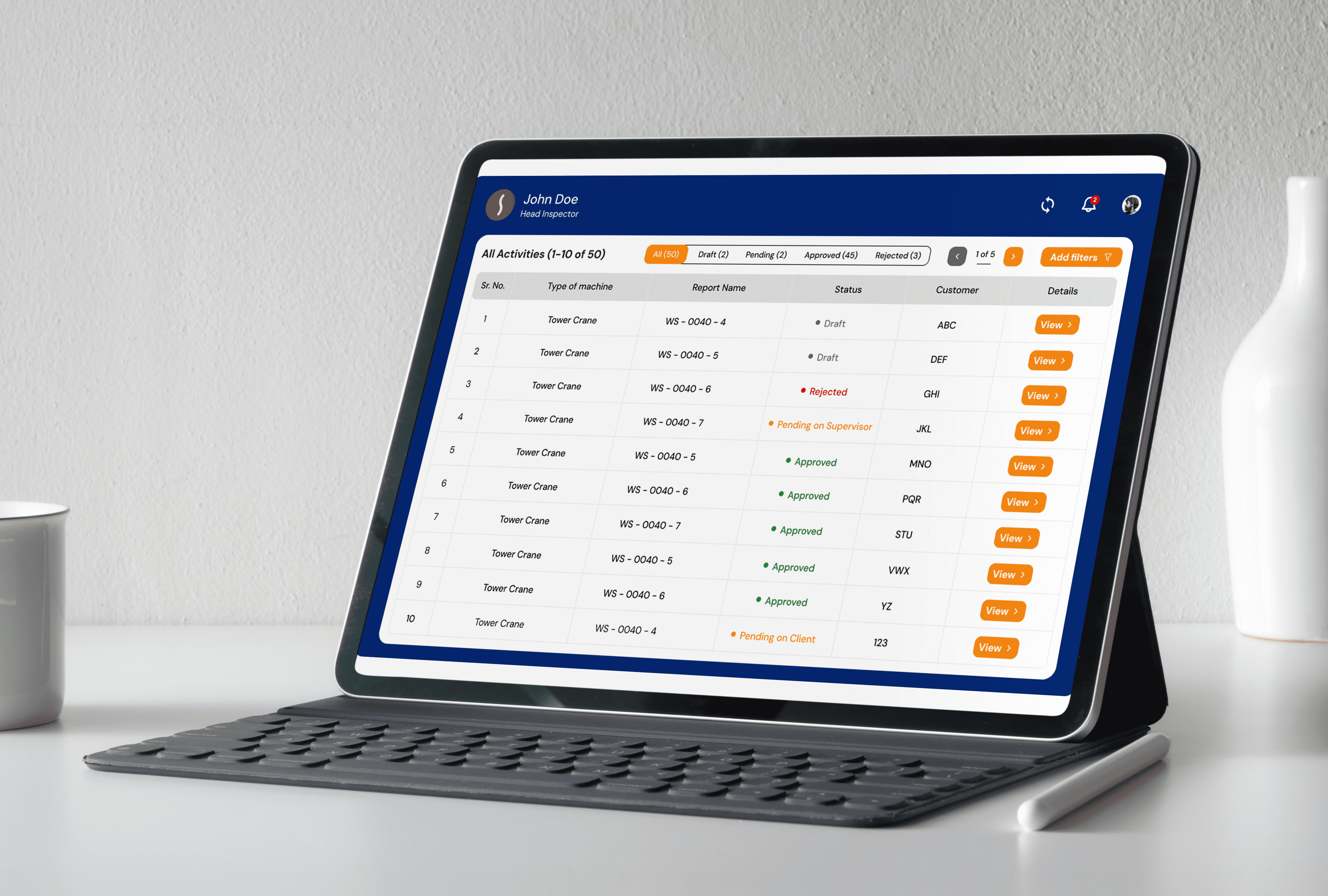

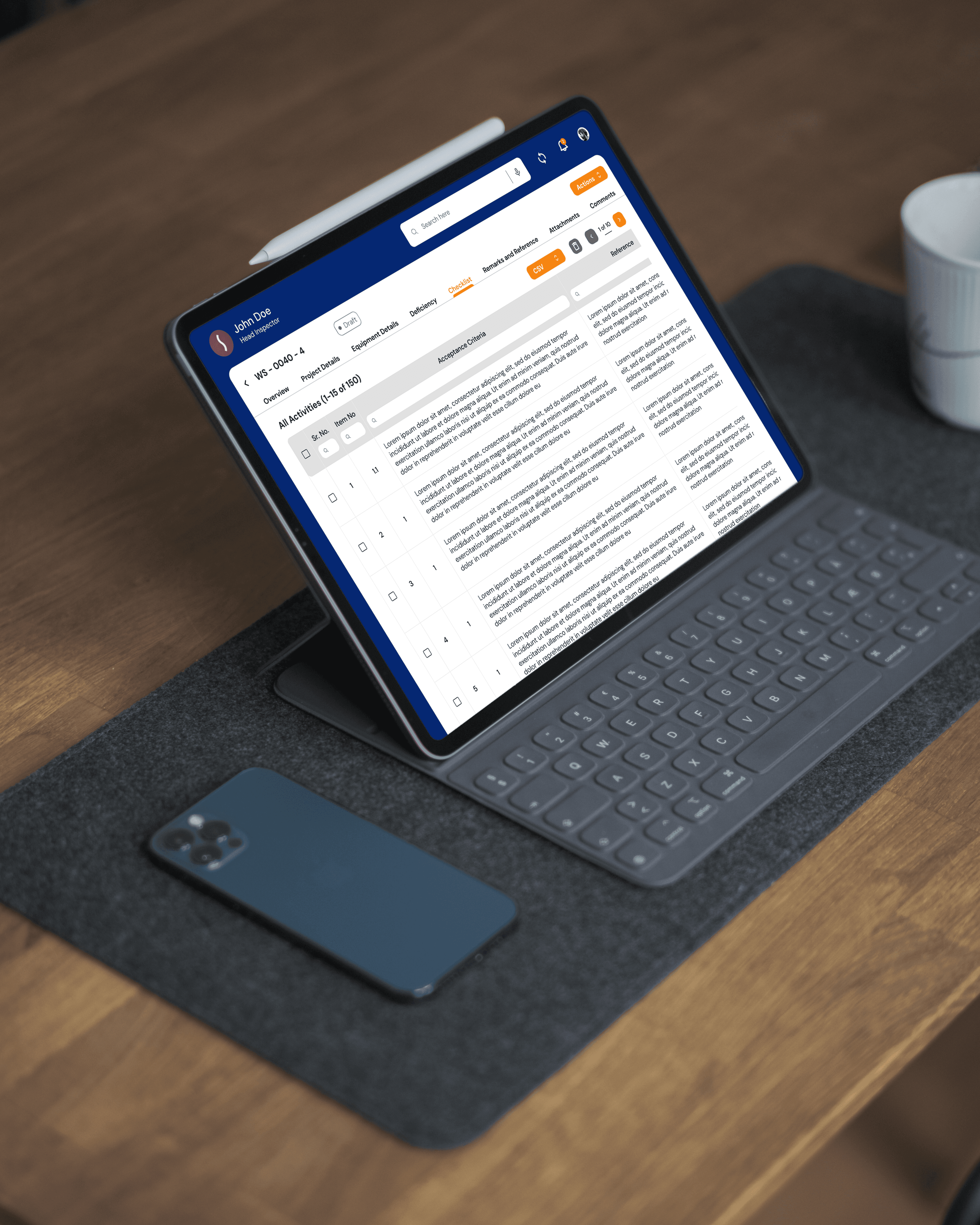

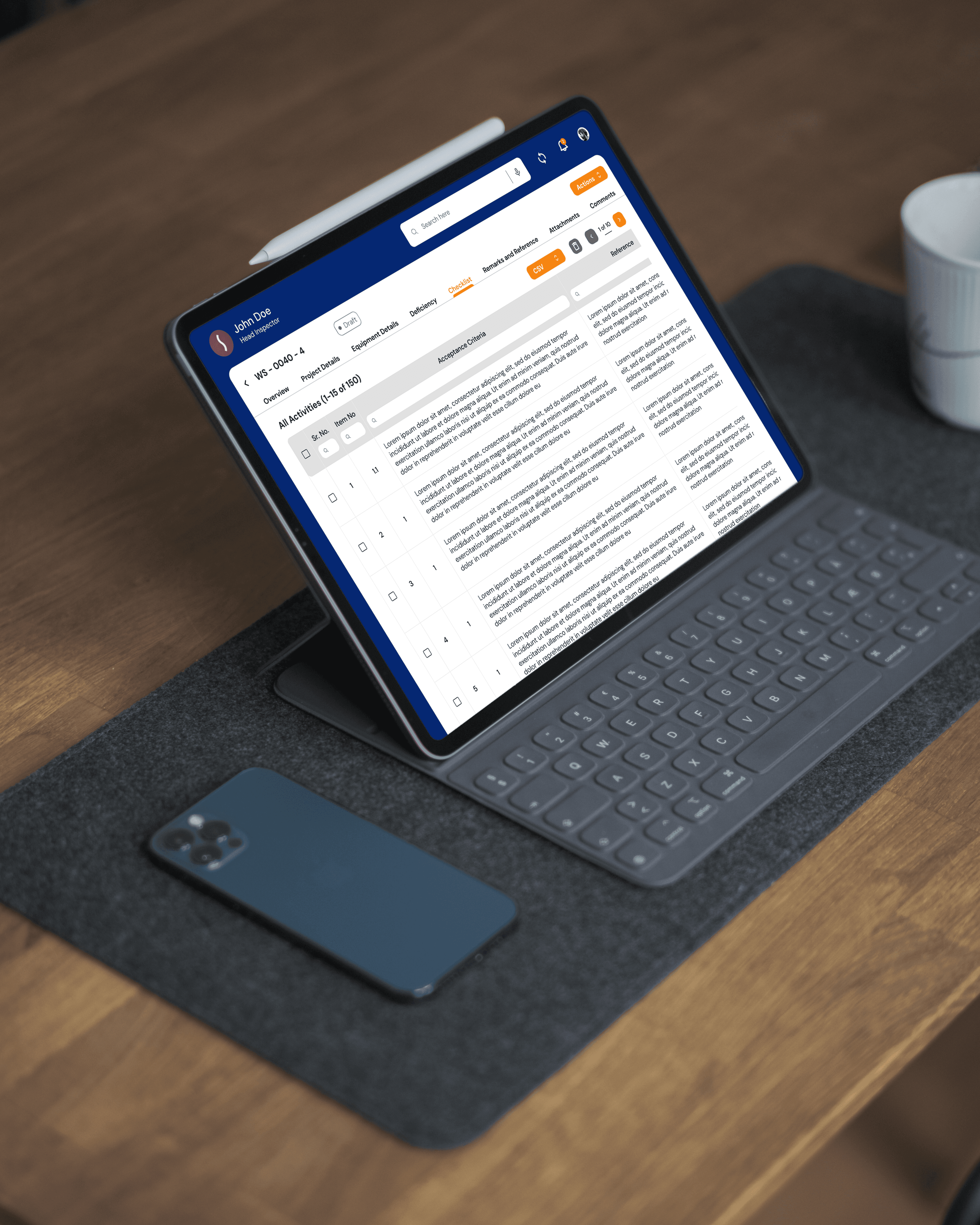

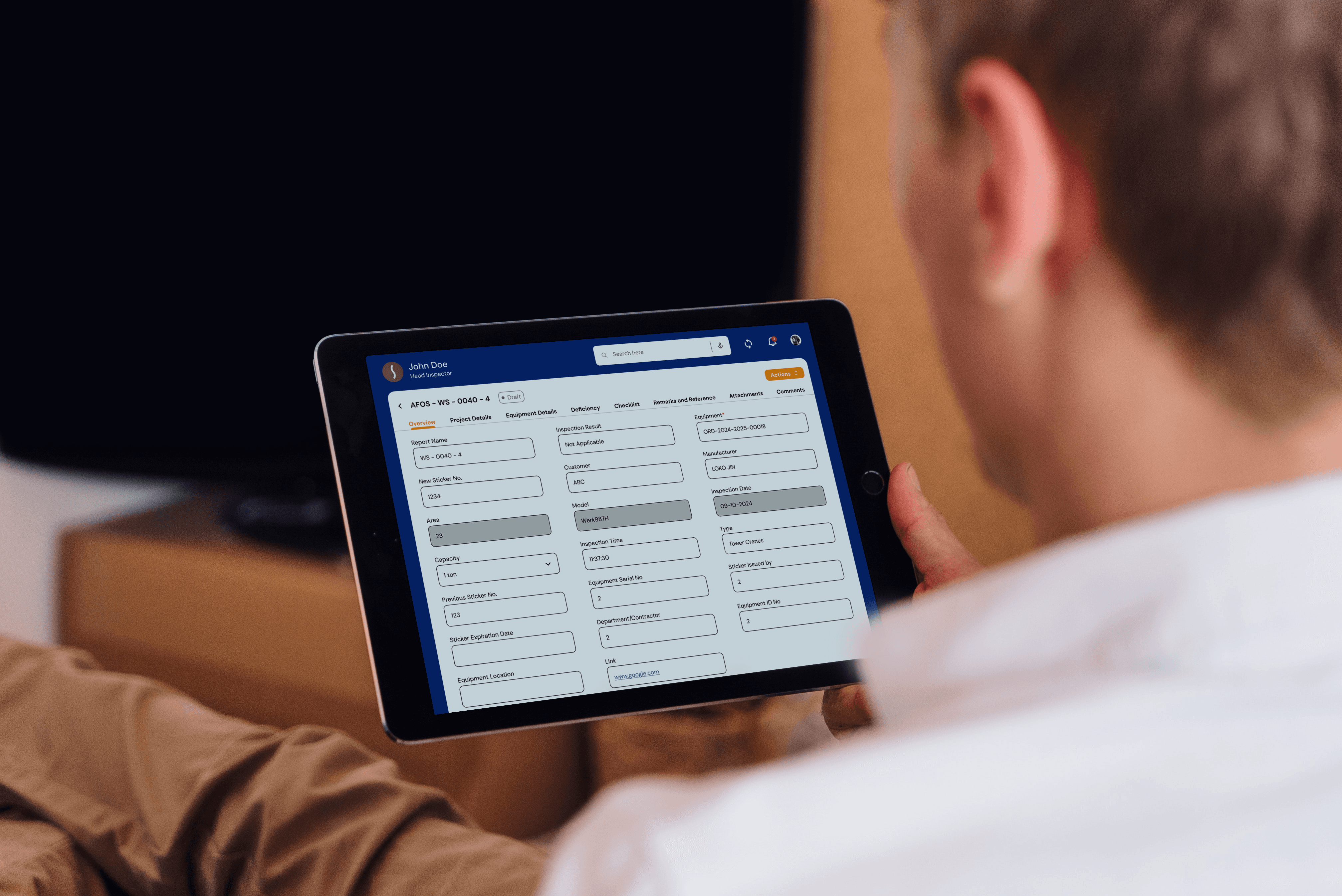

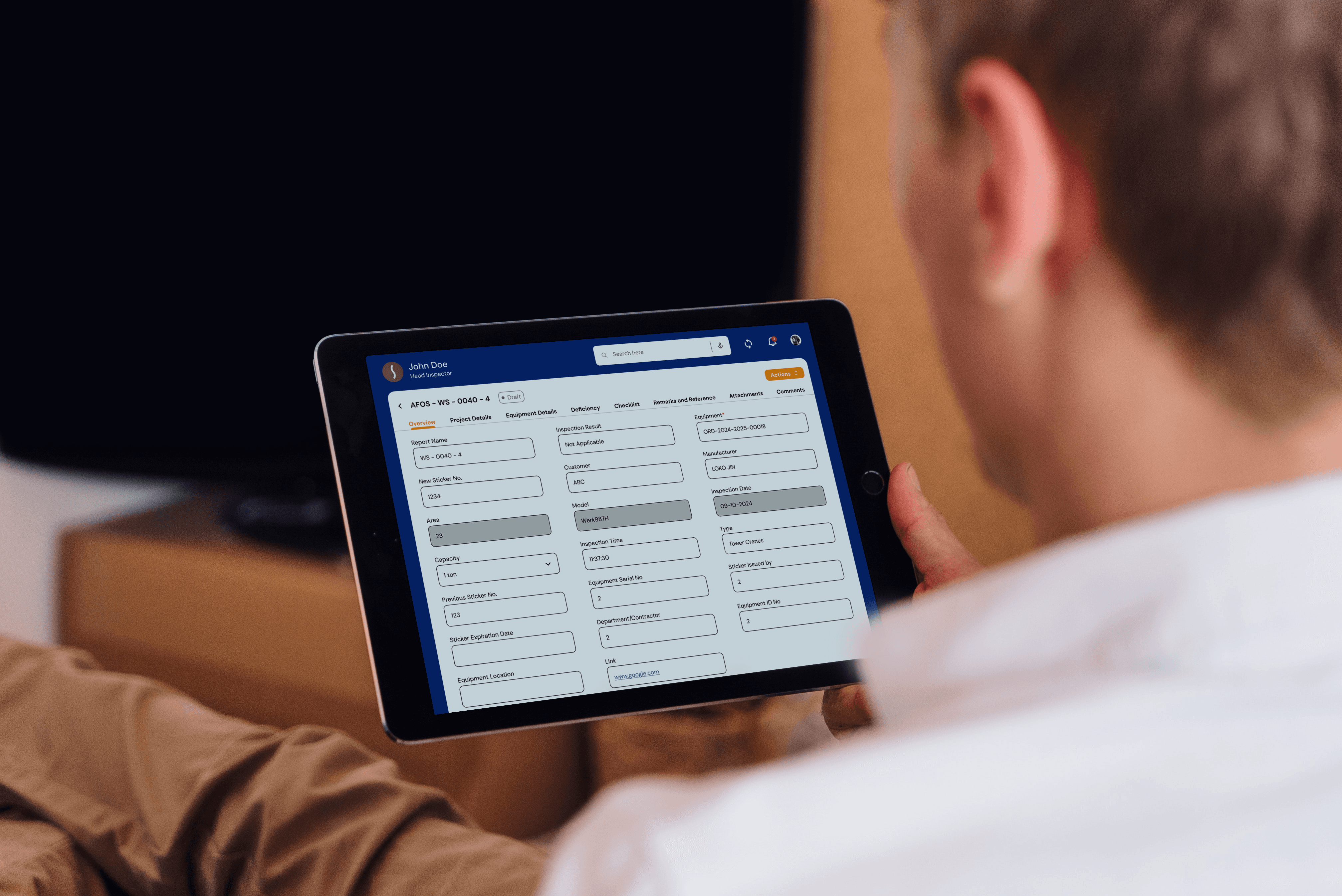

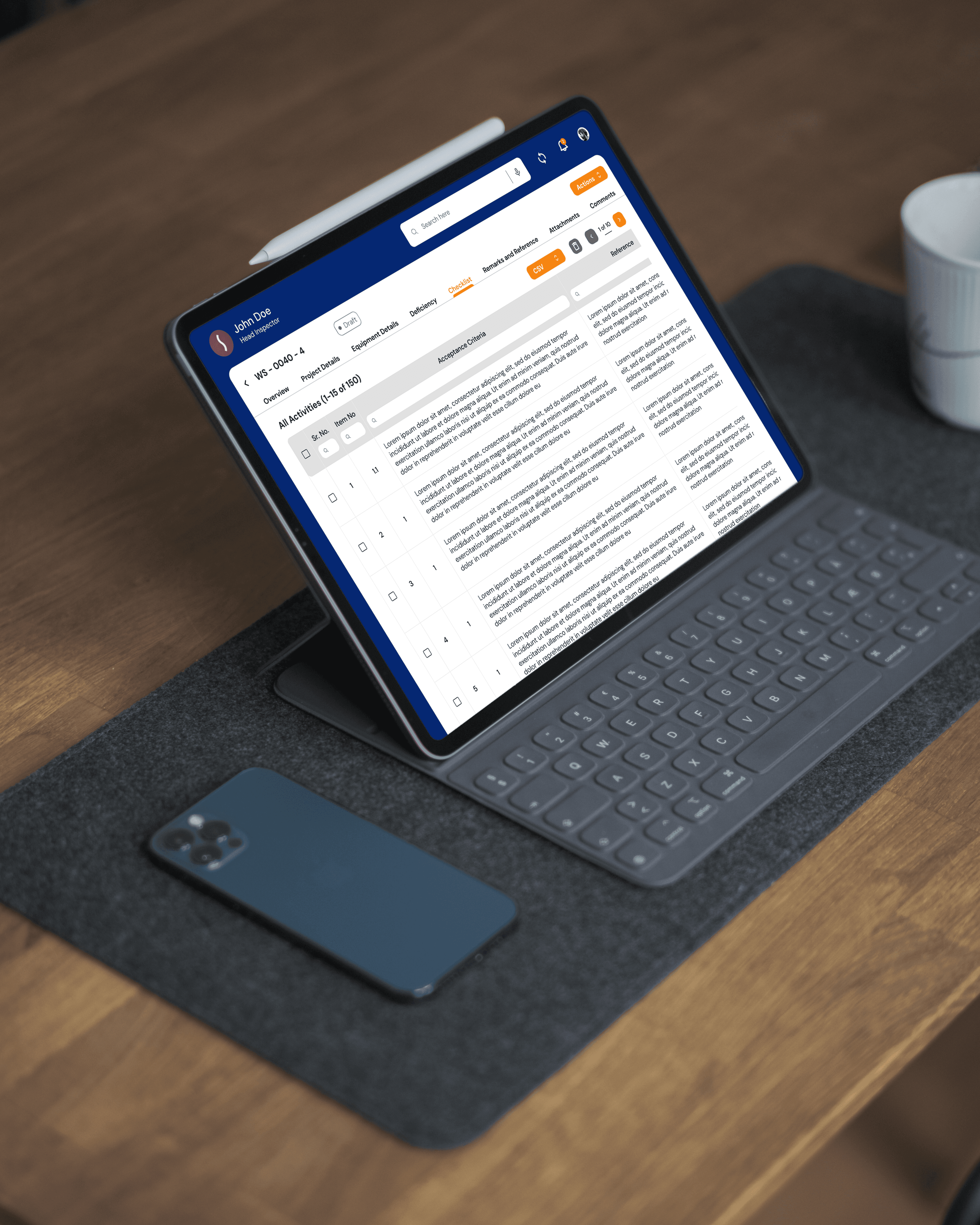

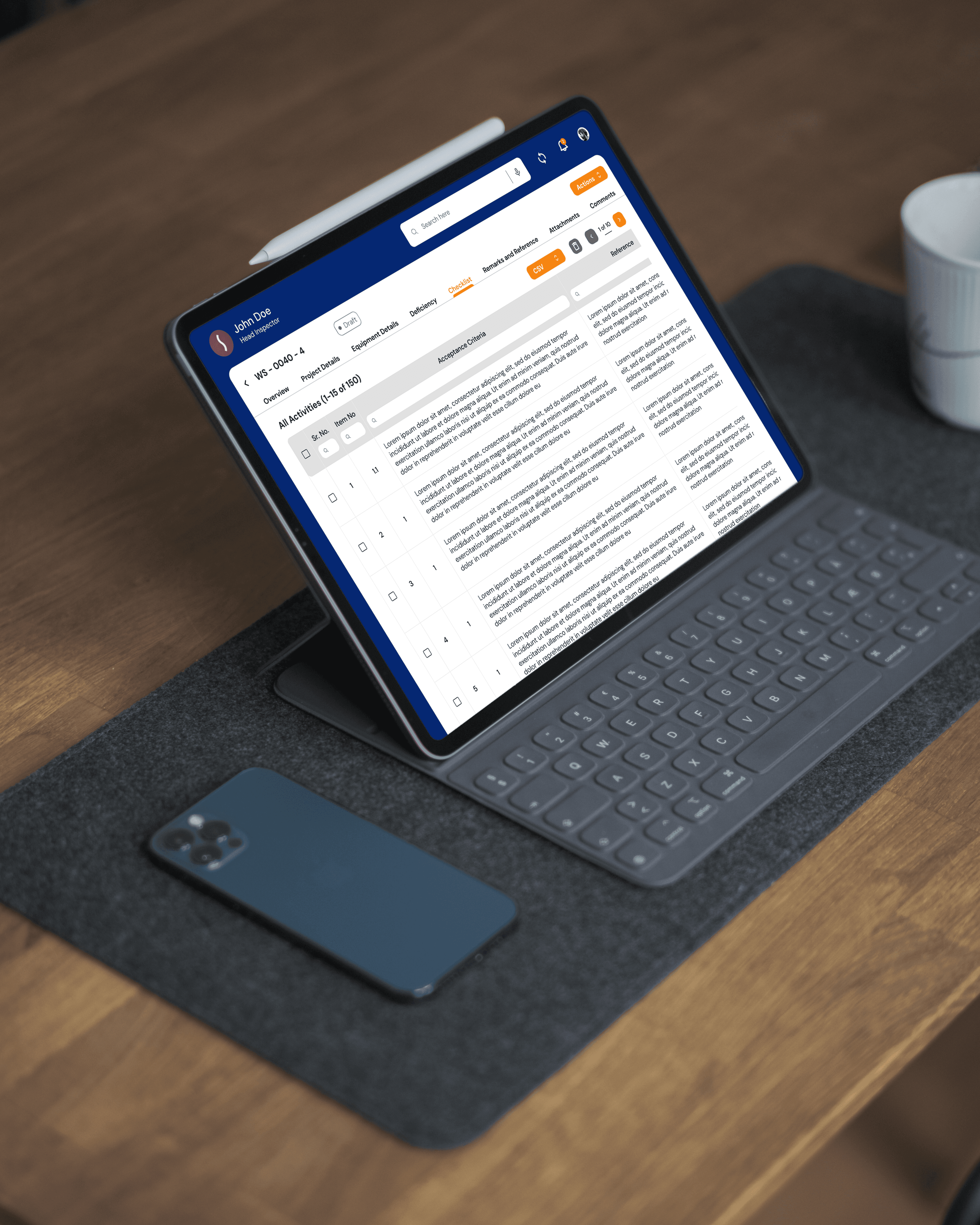

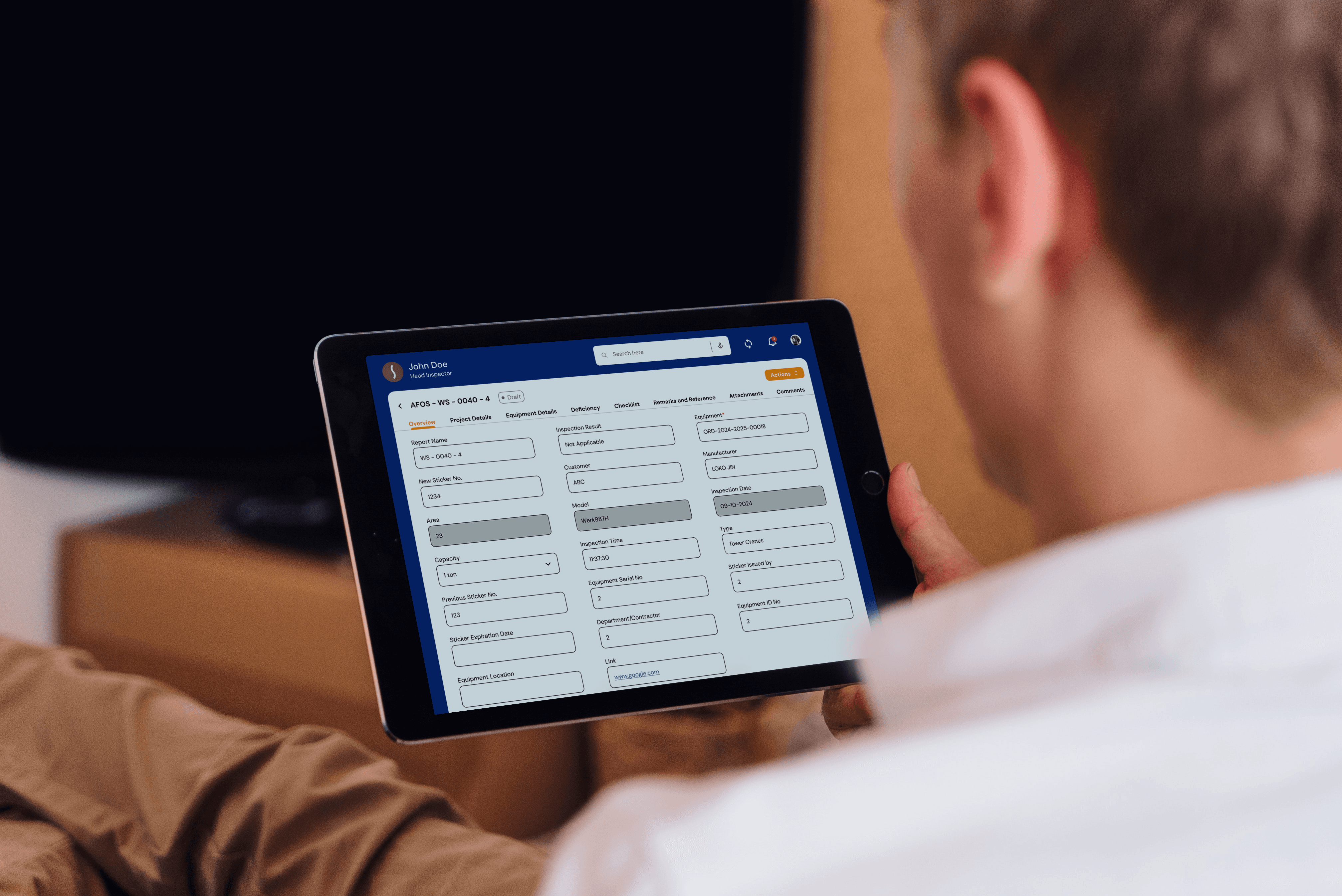

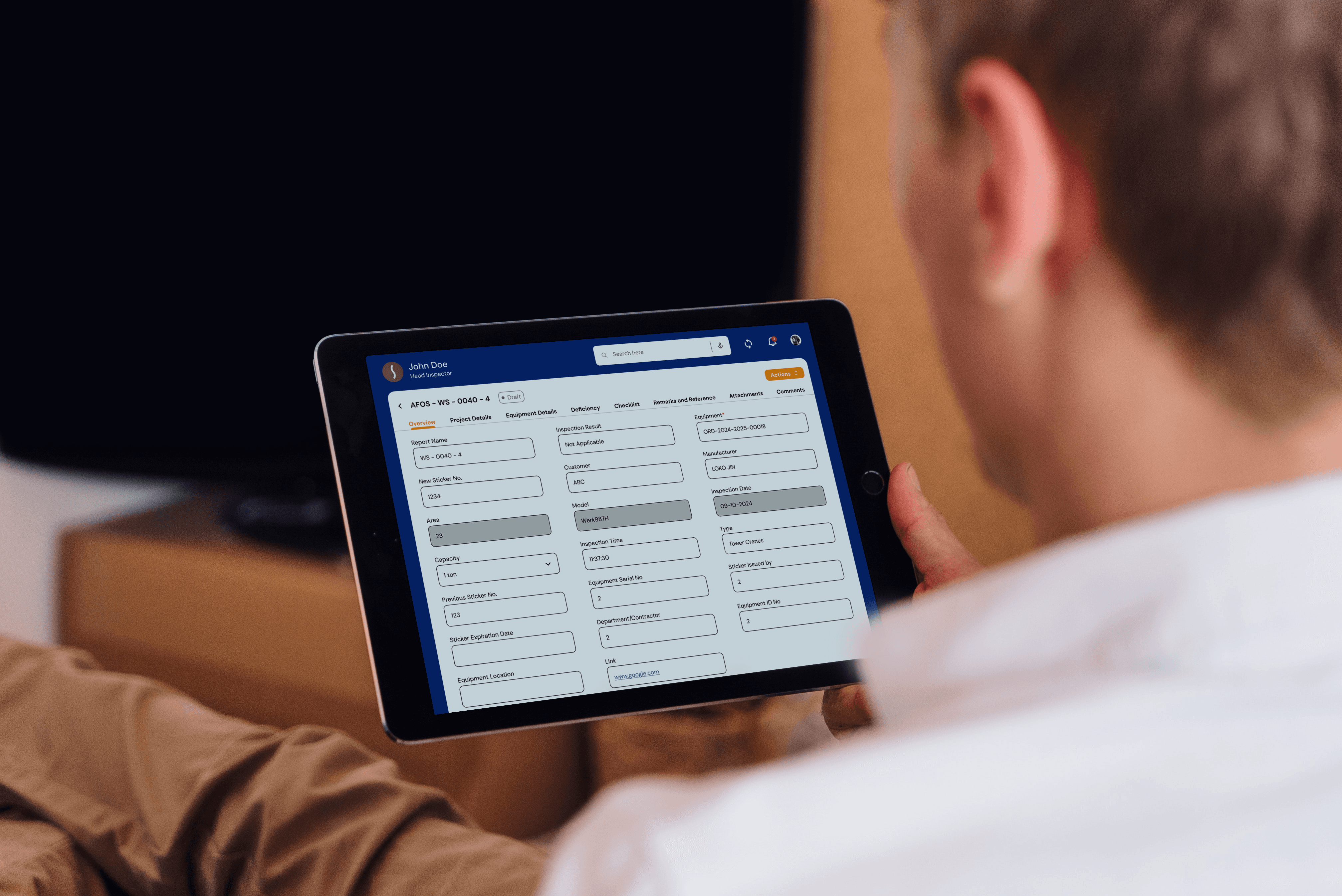

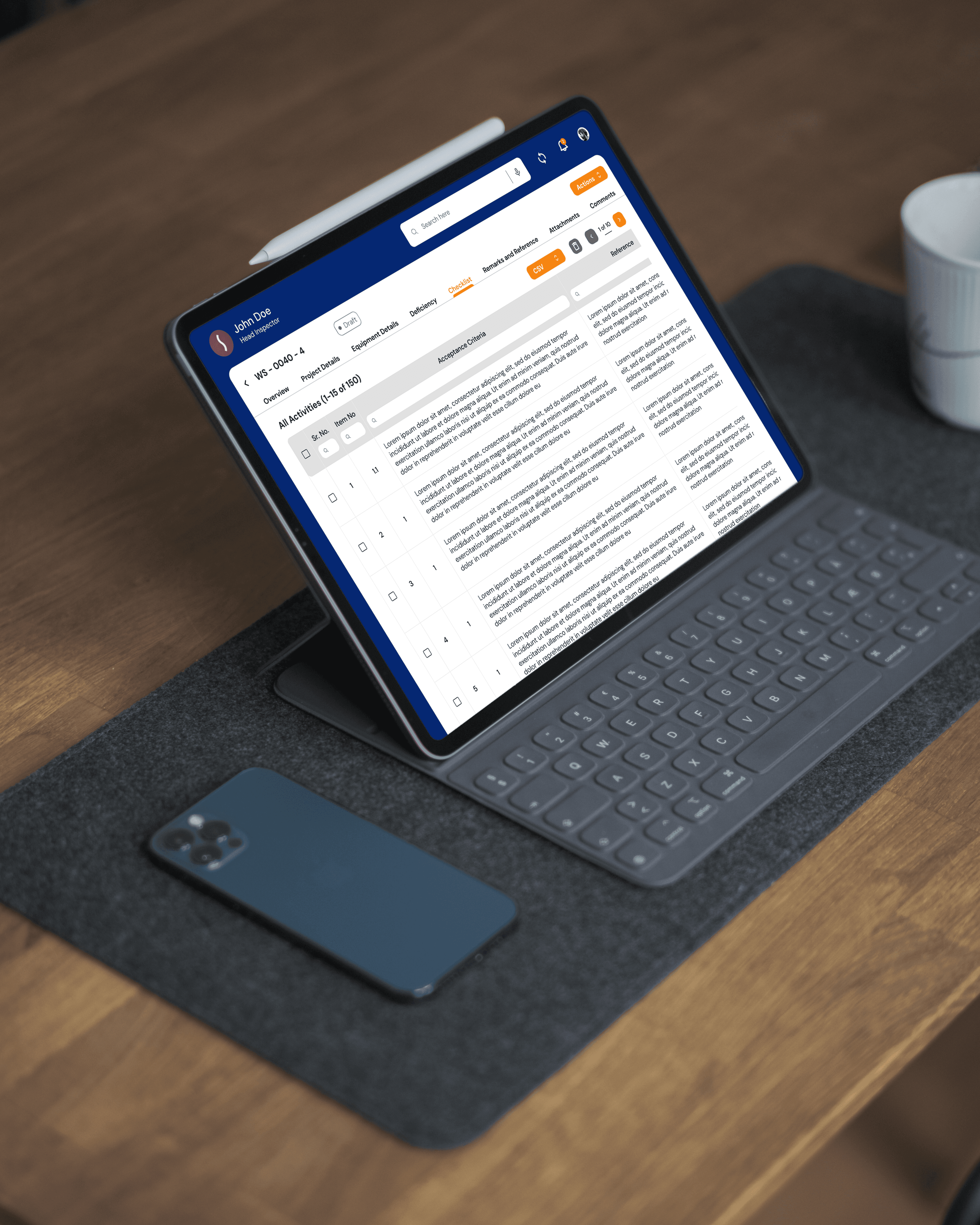

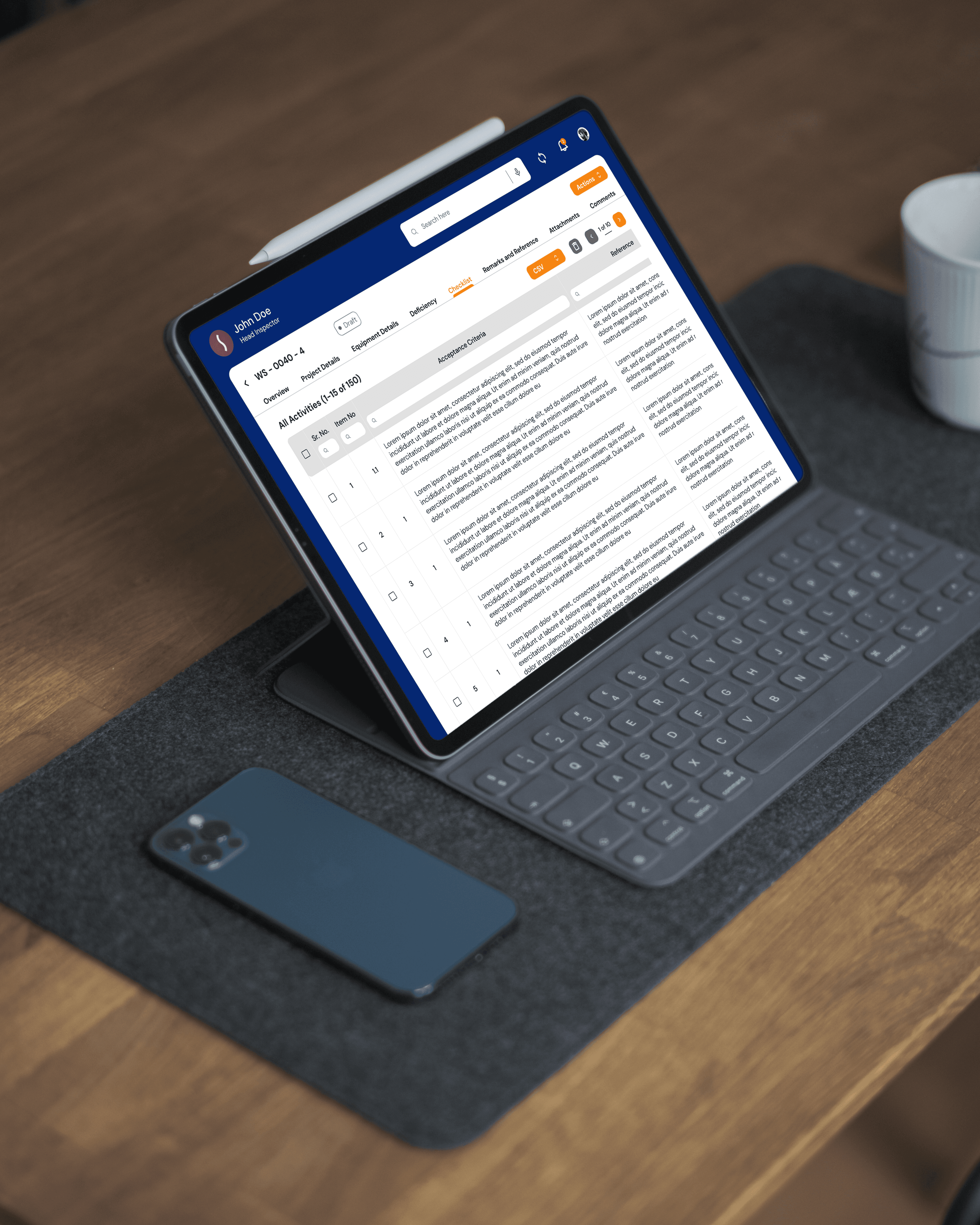

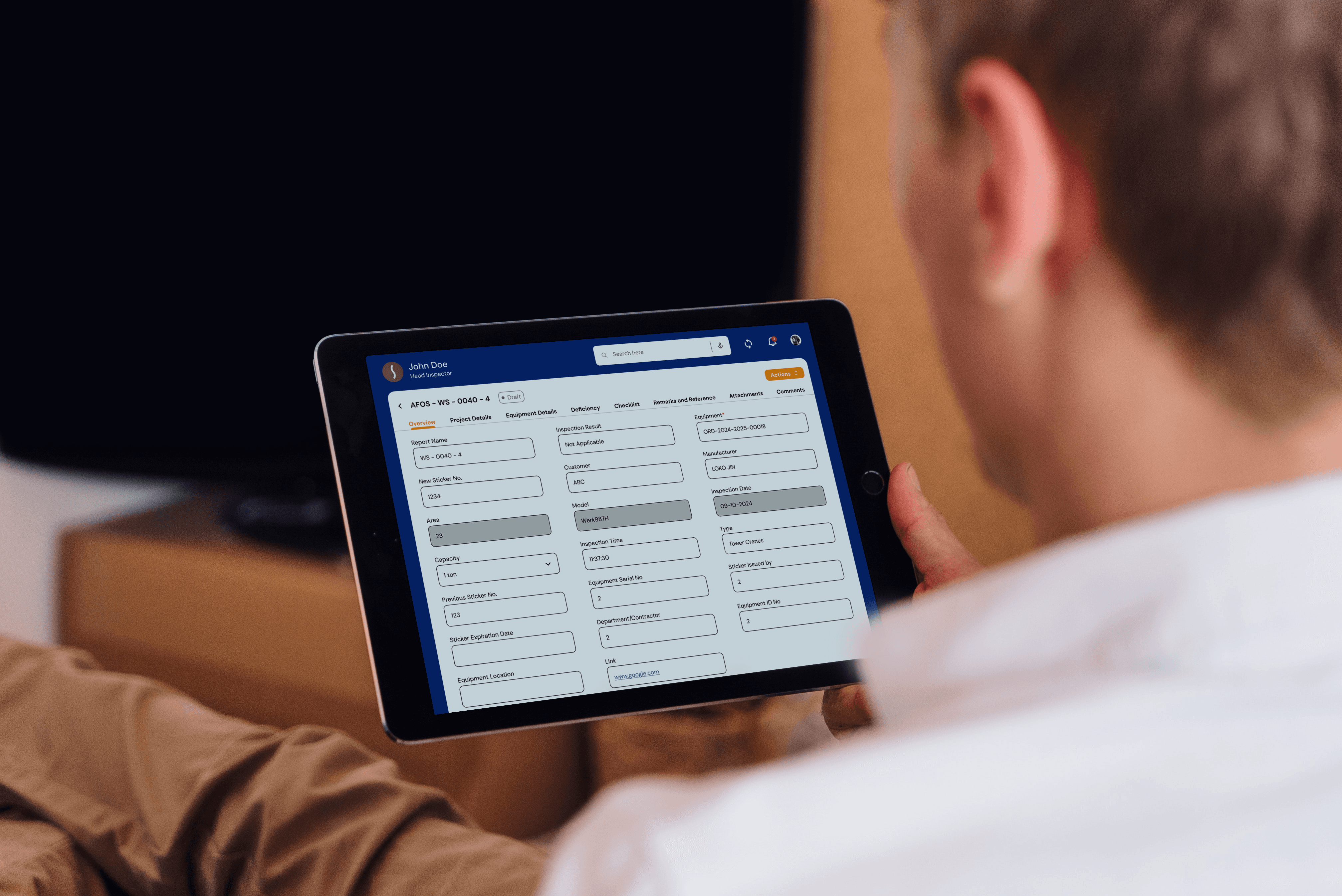

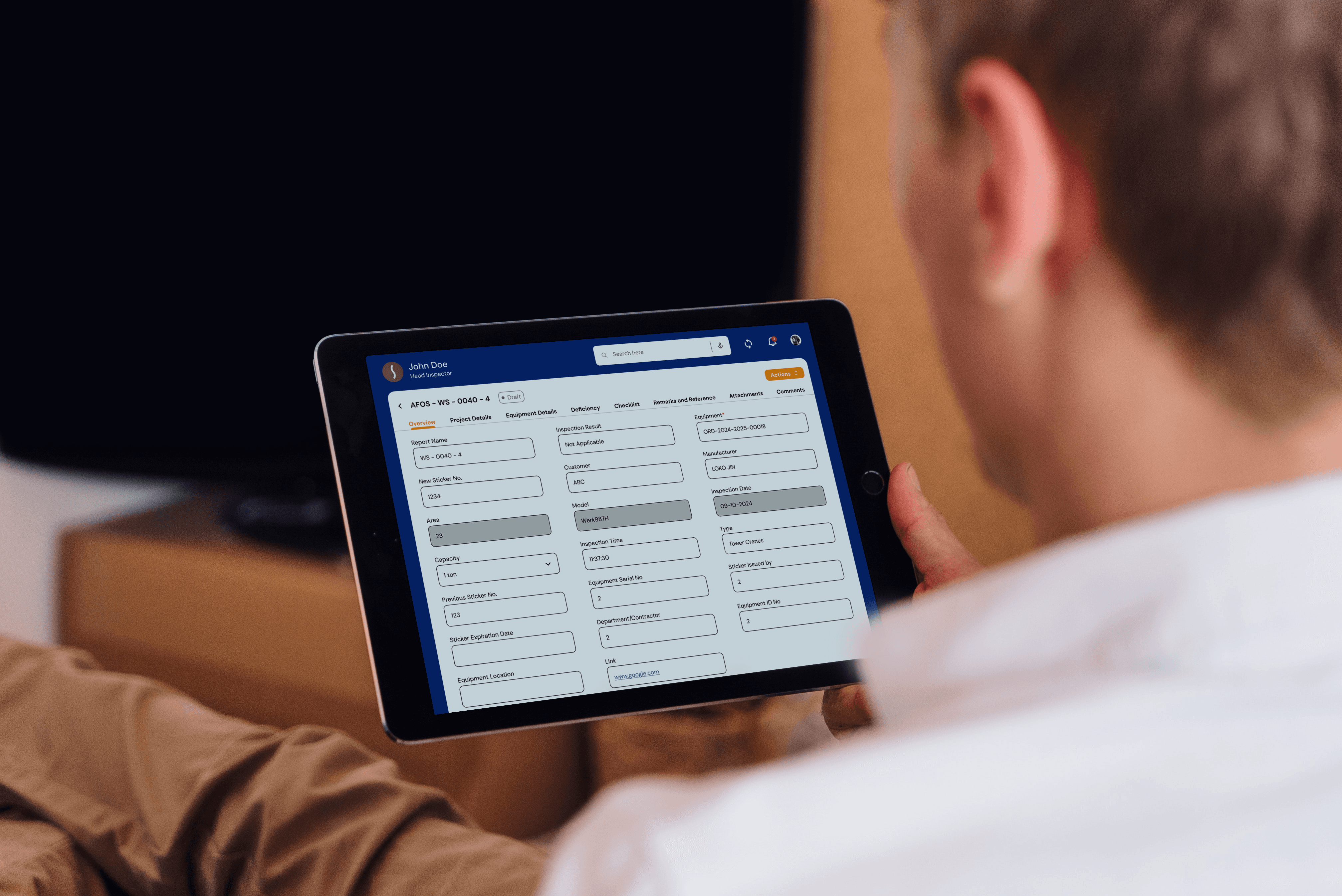

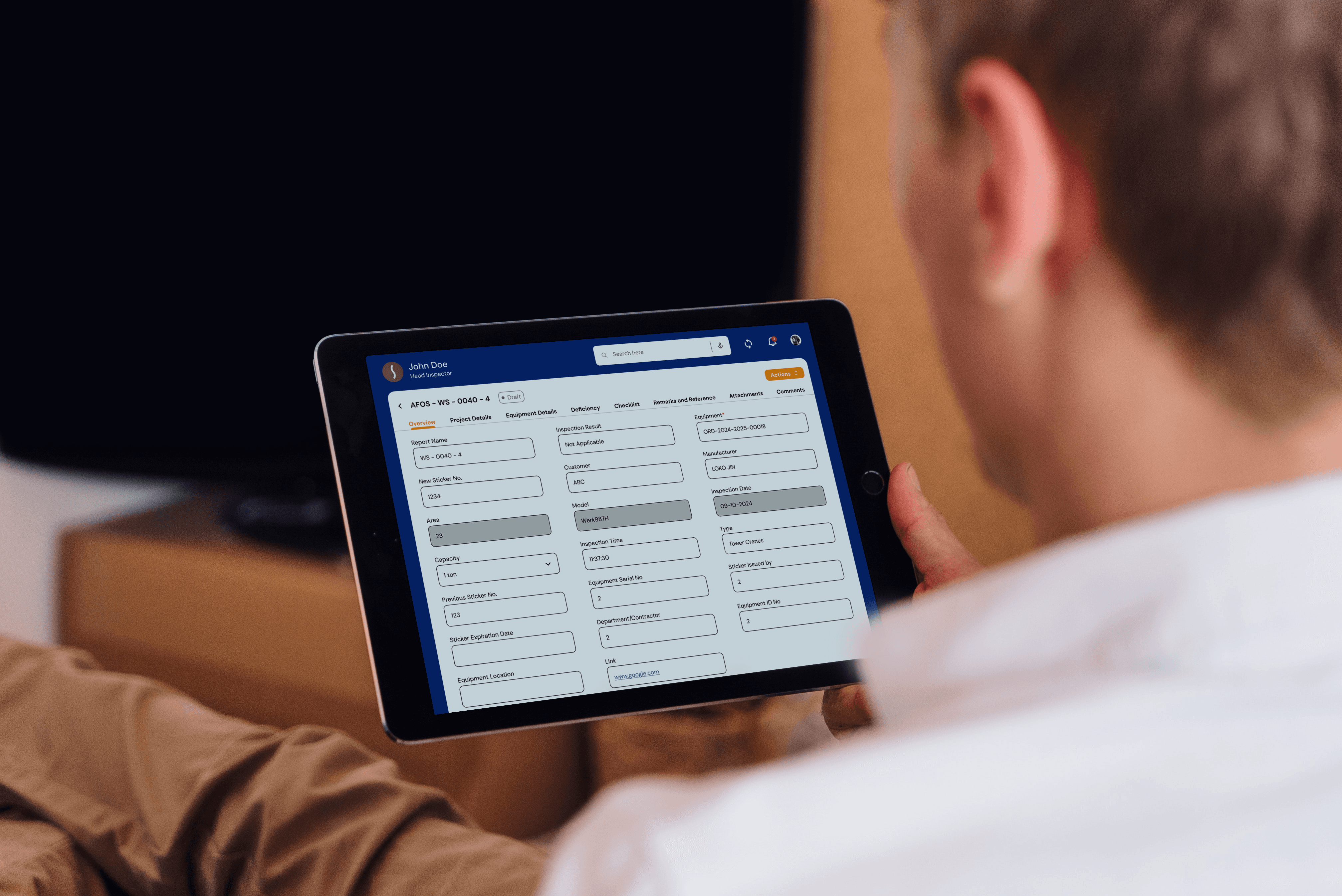

Digitizing Field Inspections for Greater Accuracy and Speed

Designed a field-ready NDT inspection app that cut reporting time by 50% and improved data accuracy by 40%.

Year :

2025

Industry :

NDT-Tech

Project Duration :

10 weeks

Problem :

On-site NDT (Non-Destructive Testing) inspectors were relying on manual reporting methods — paper checklists, spreadsheets, and phone calls — to record and submit inspection data. This not only delayed reporting but also increased the risk of human error, missing information, and miscommunication between field teams and supervisors.

Solution :

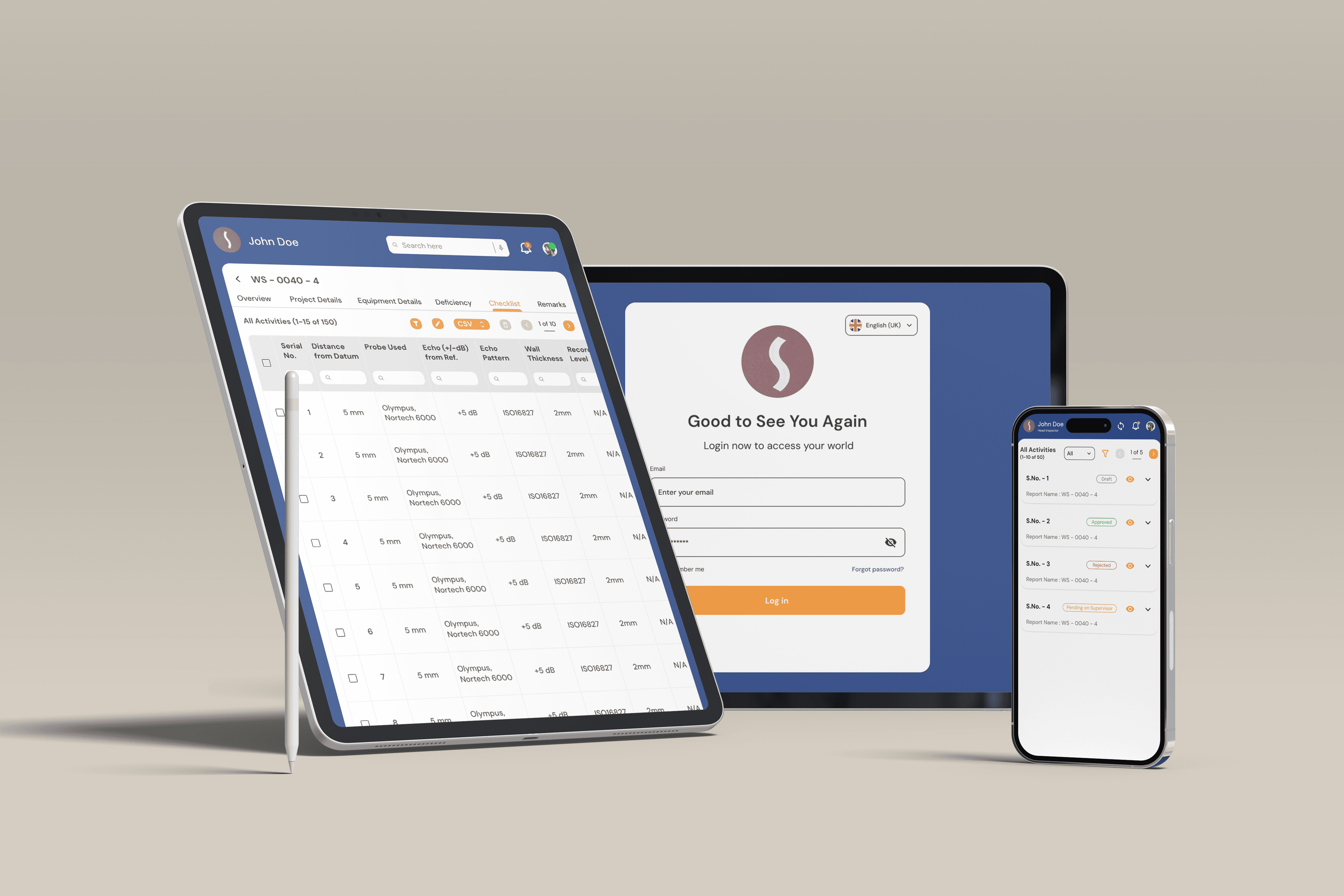

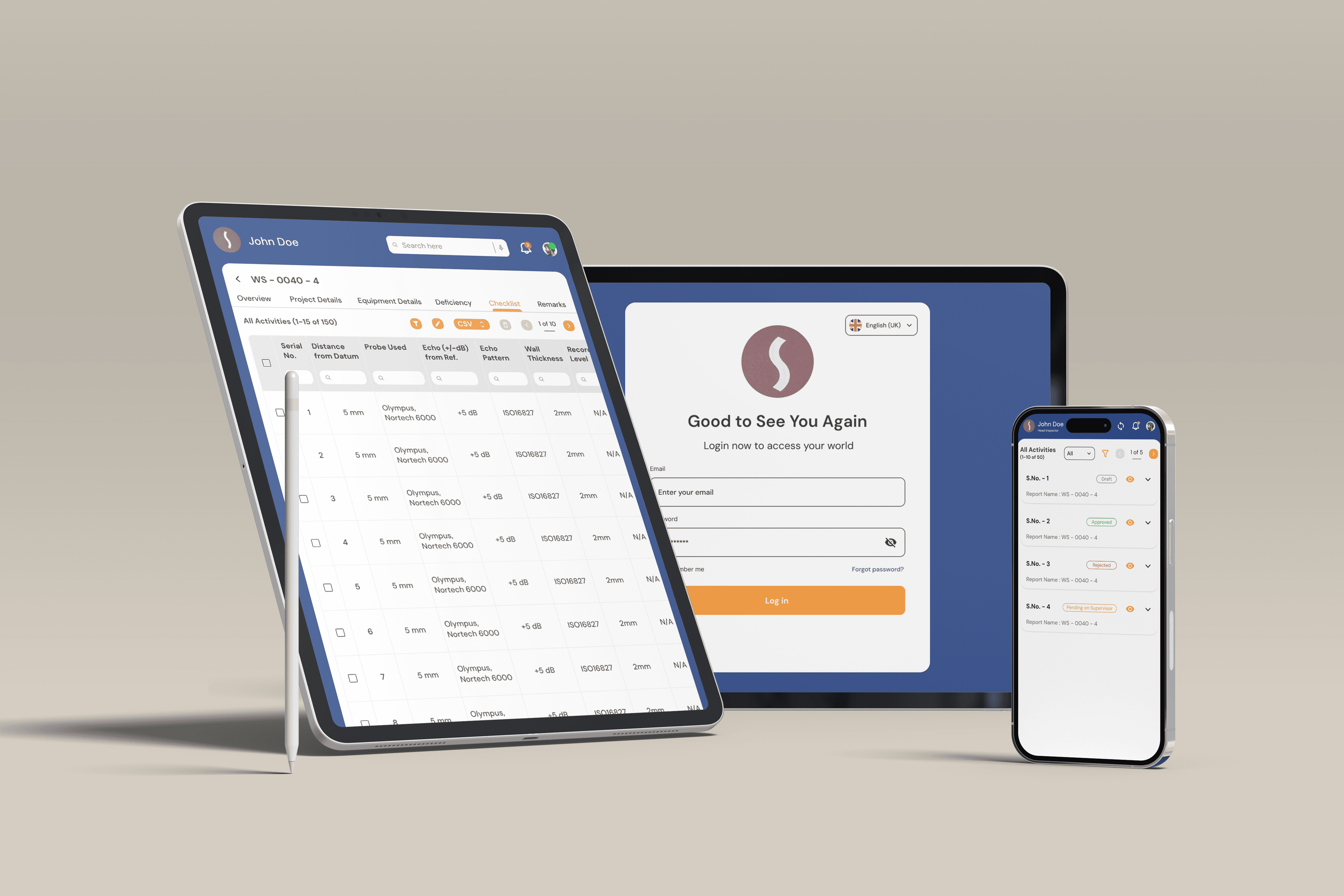

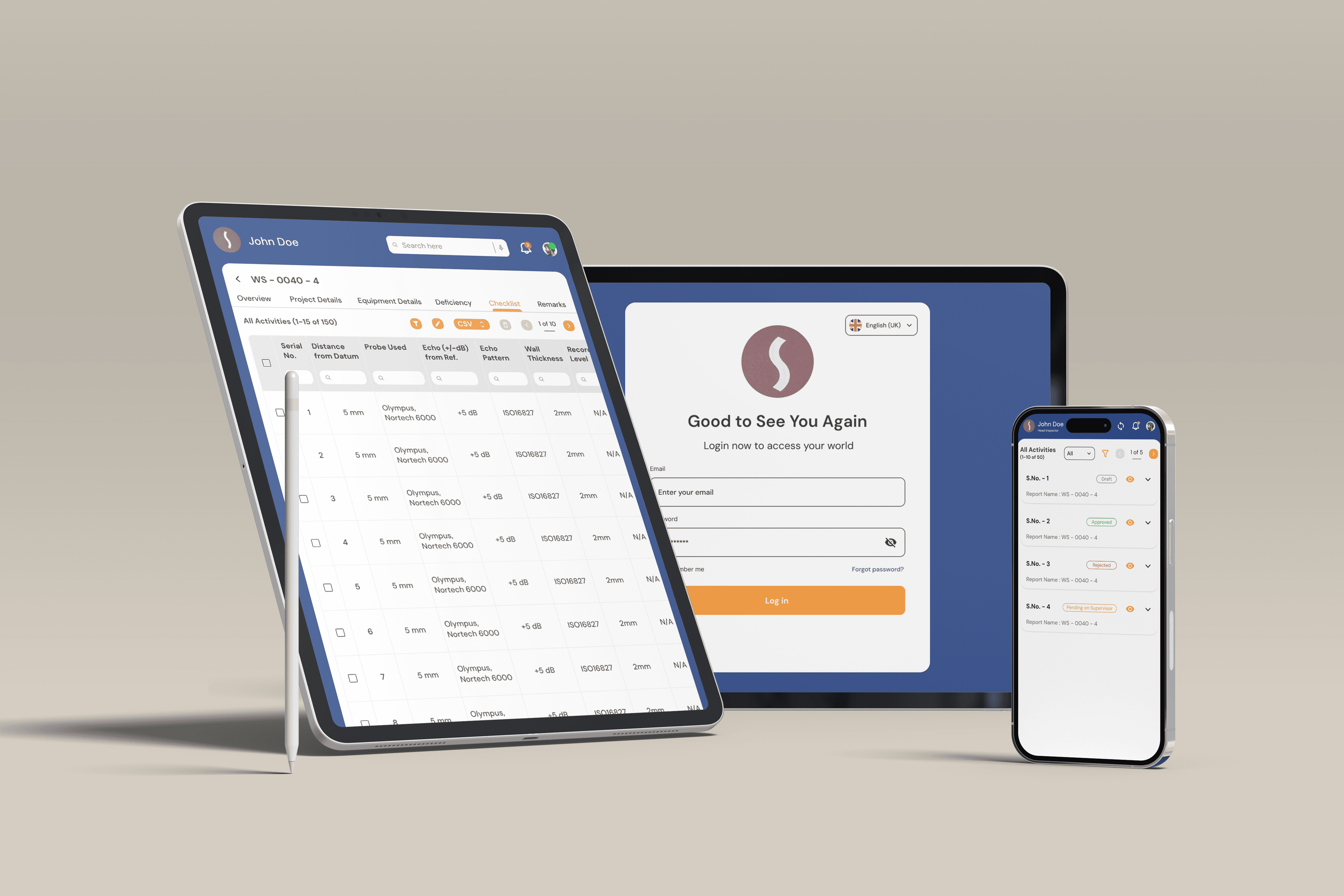

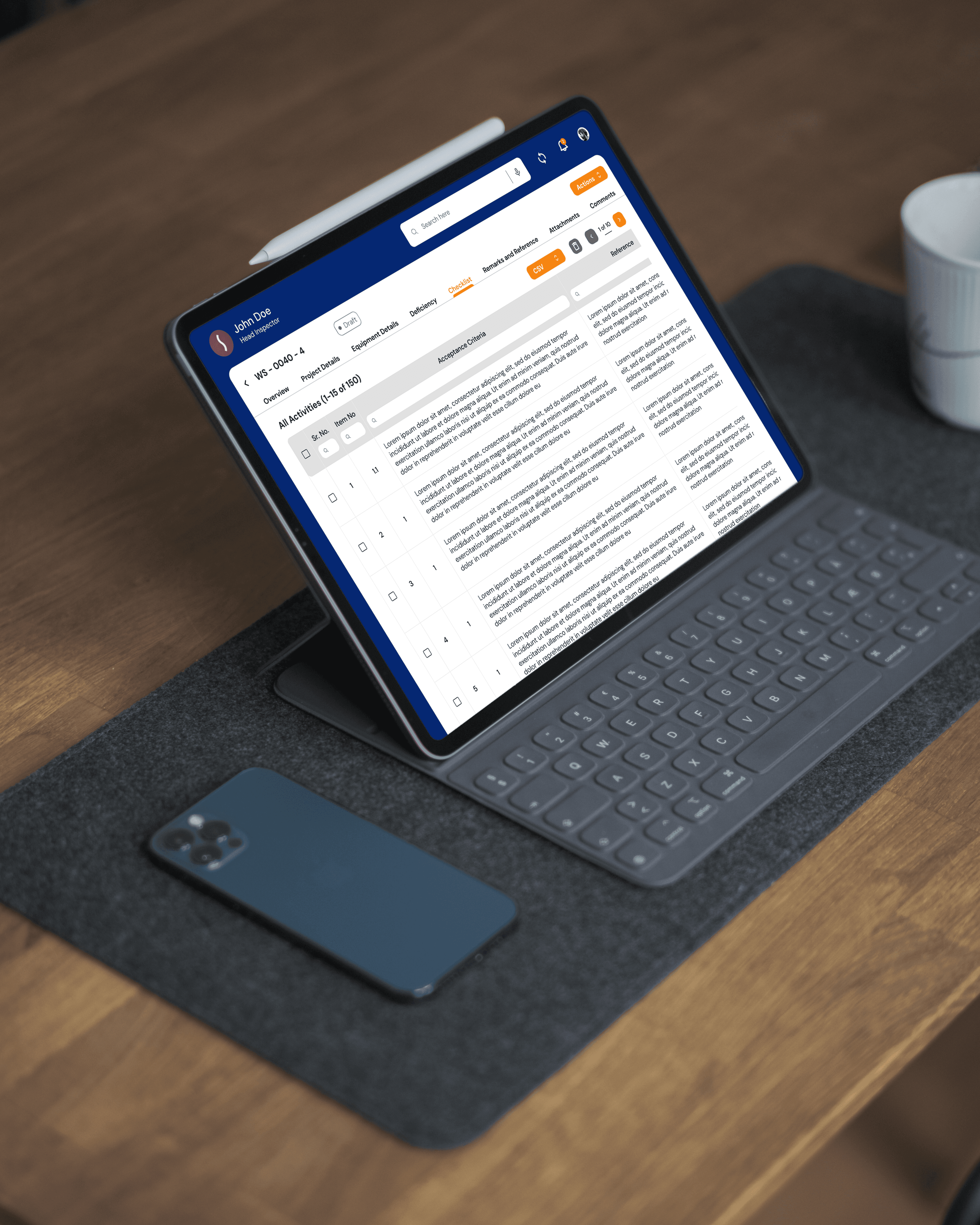

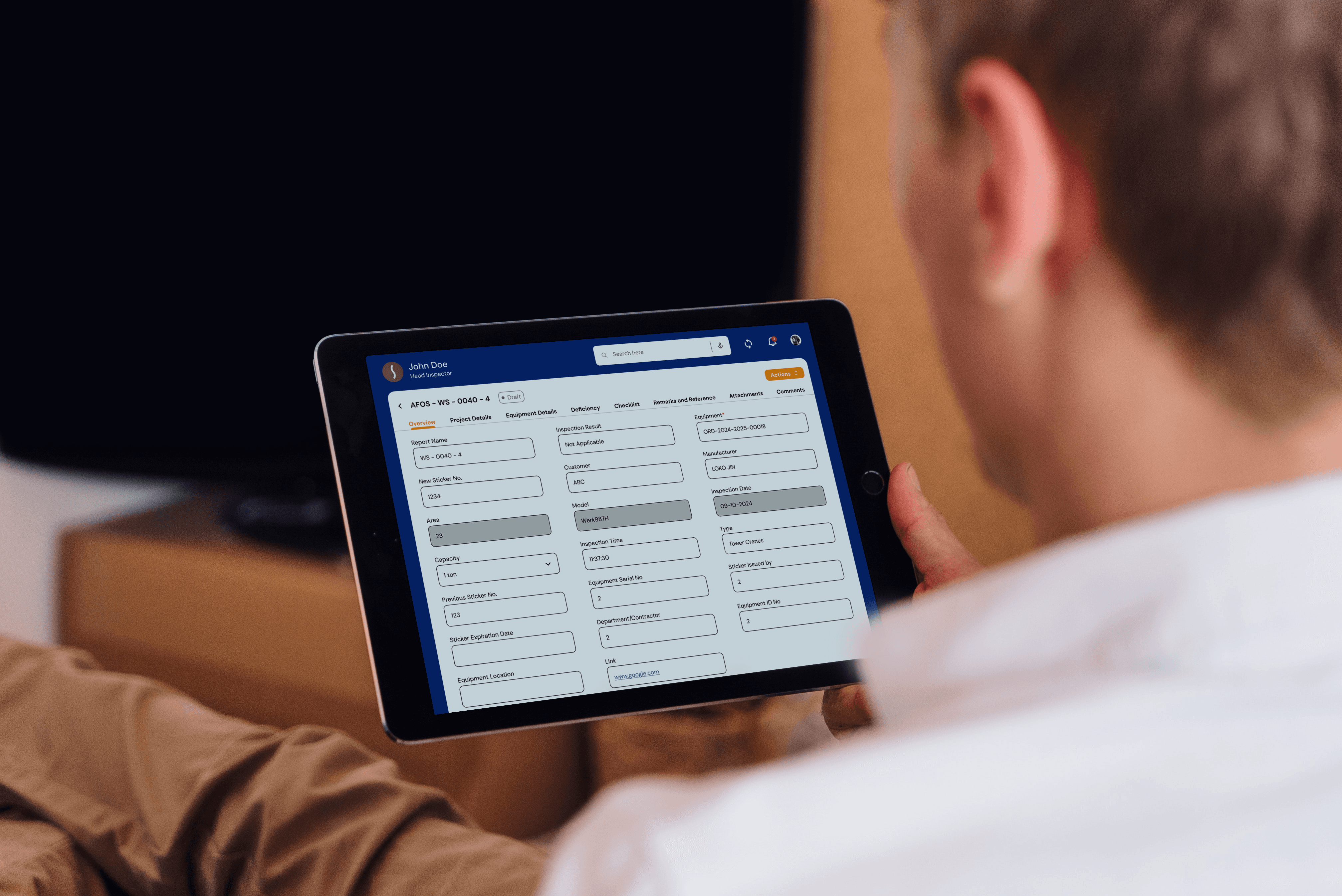

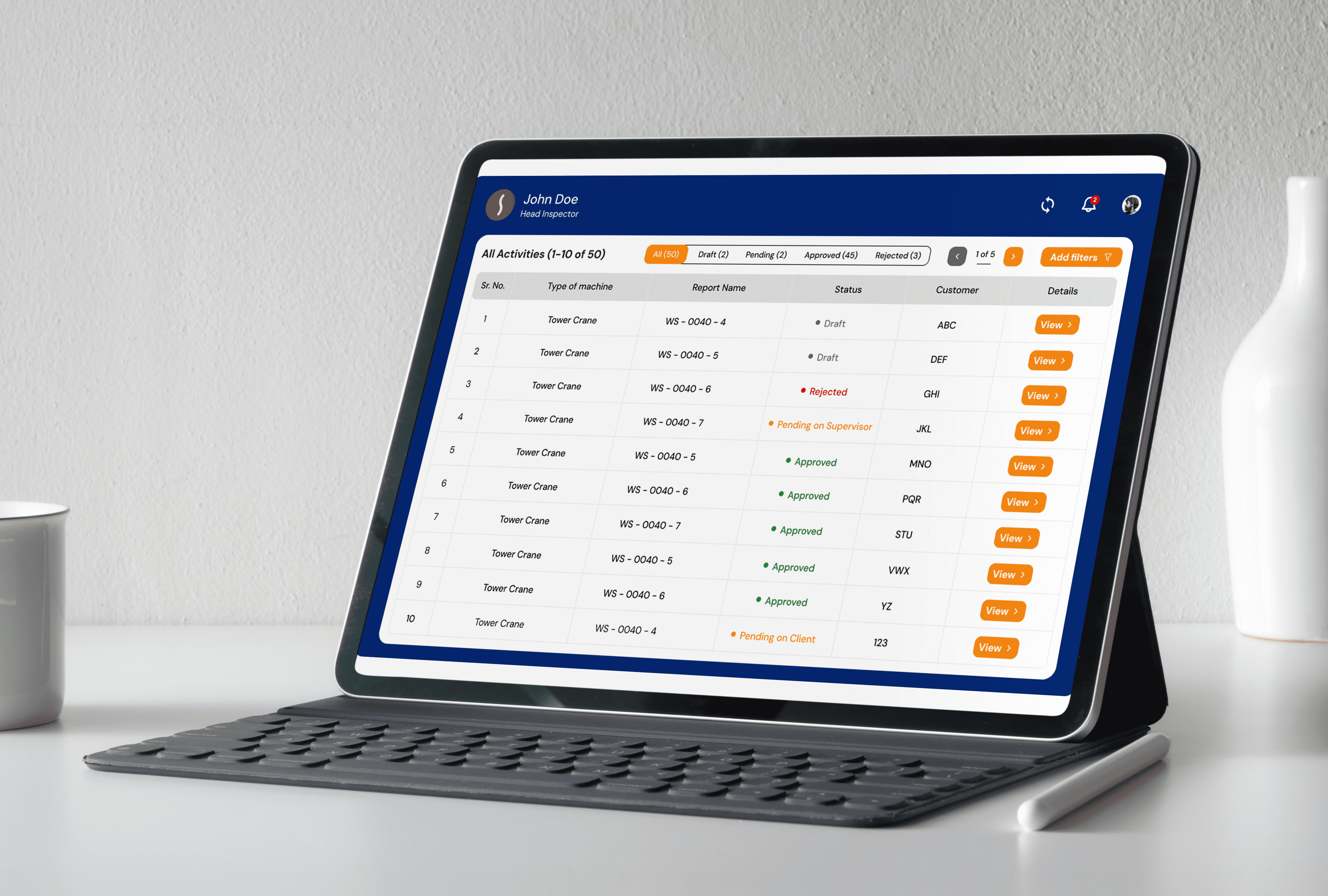

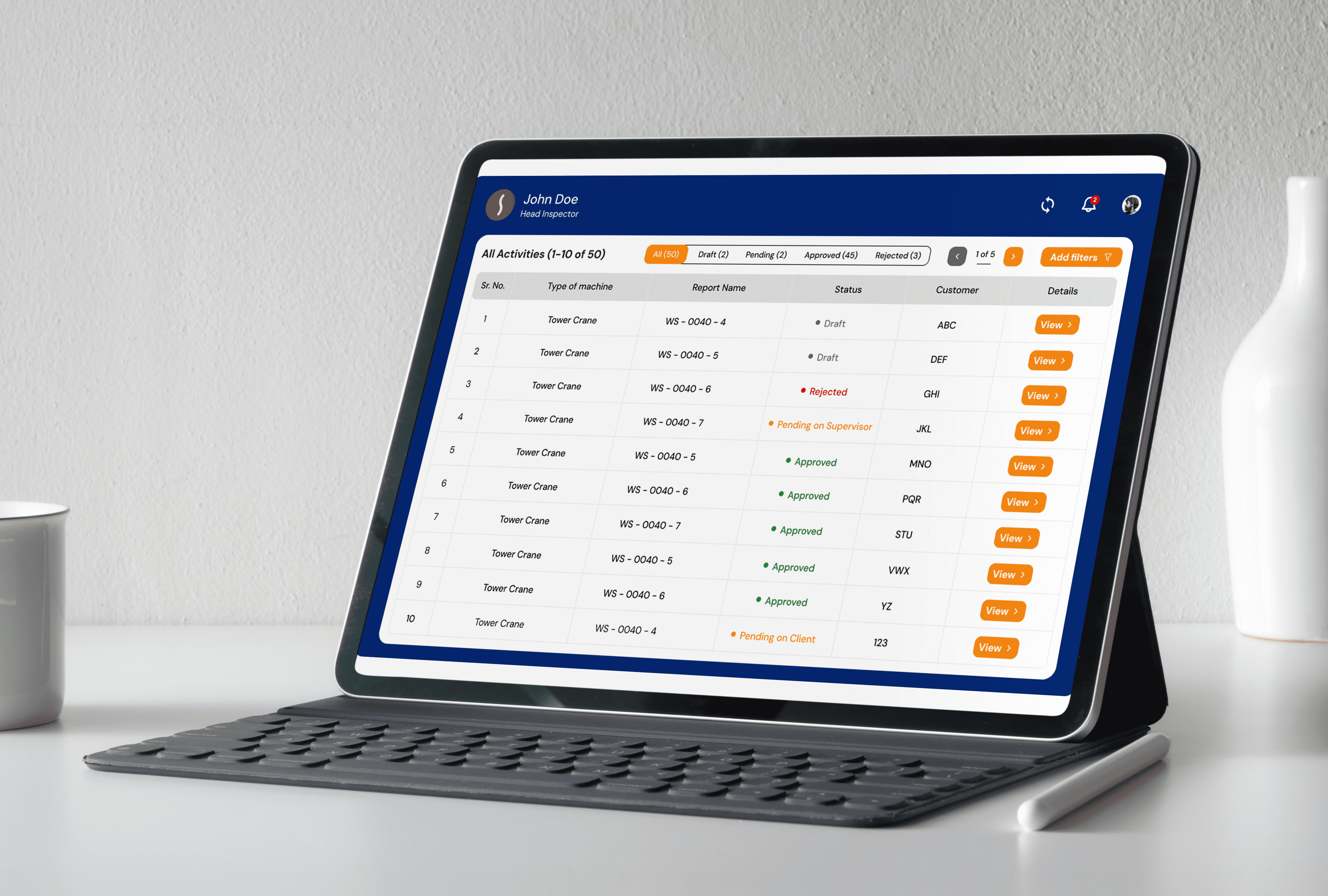

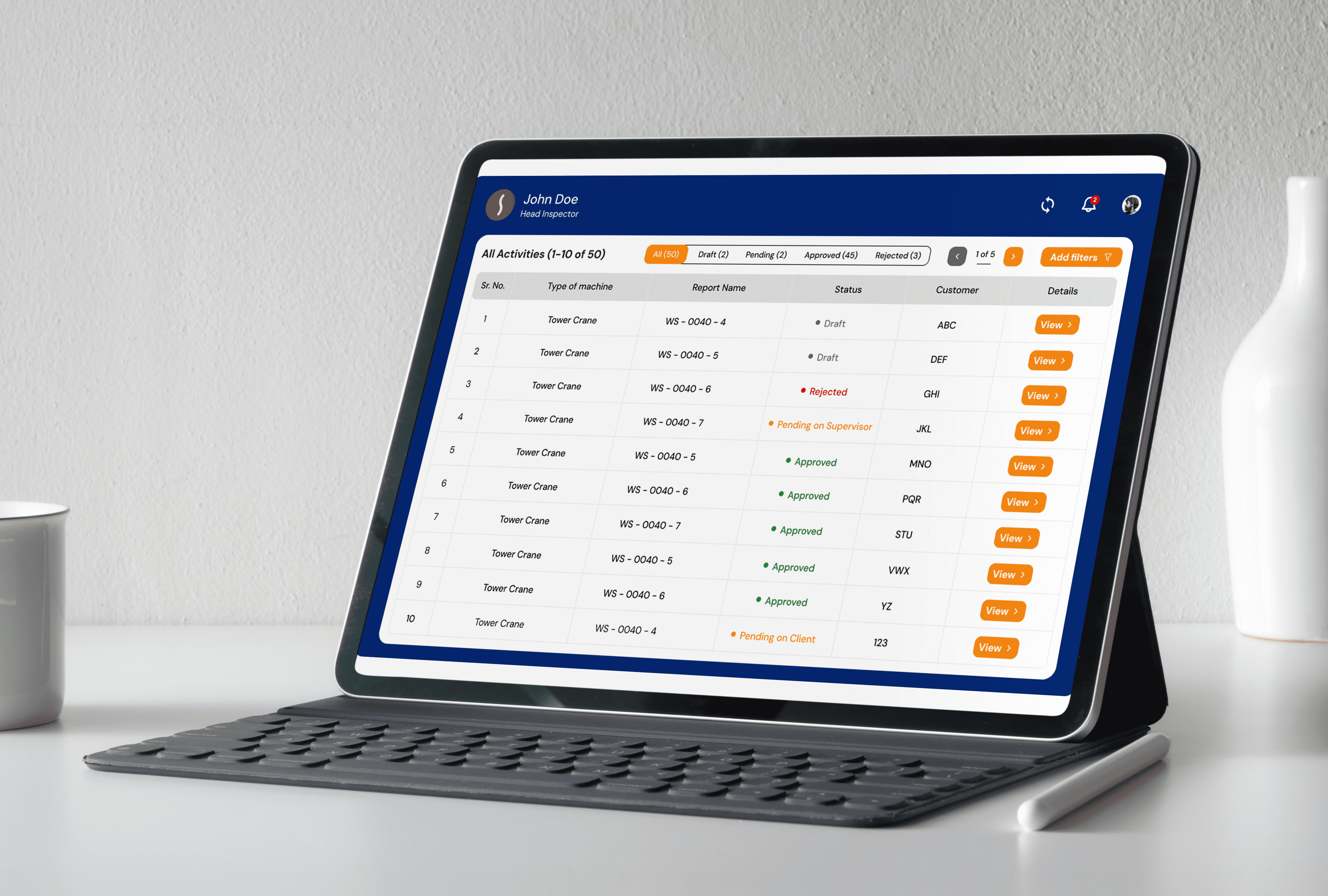

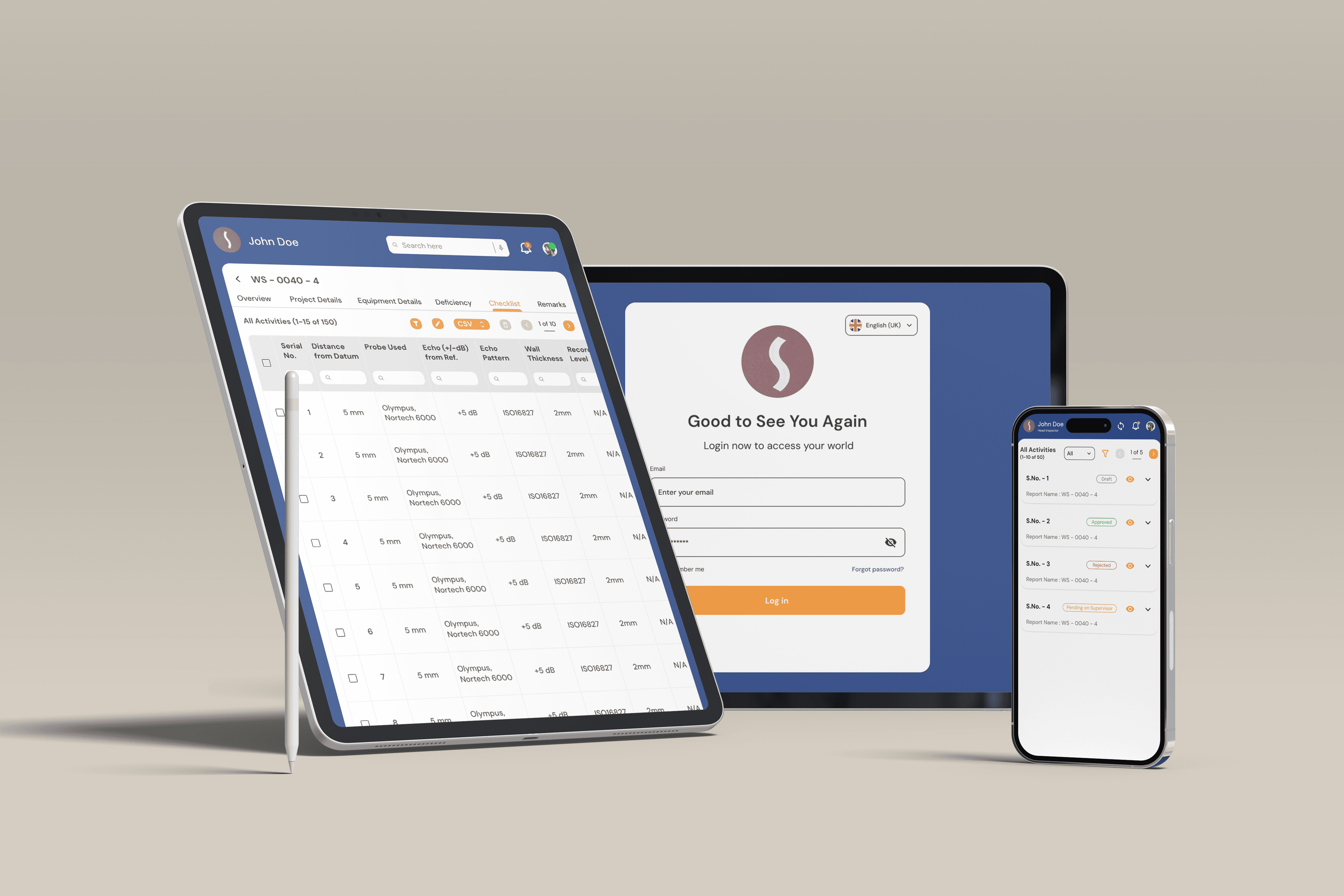

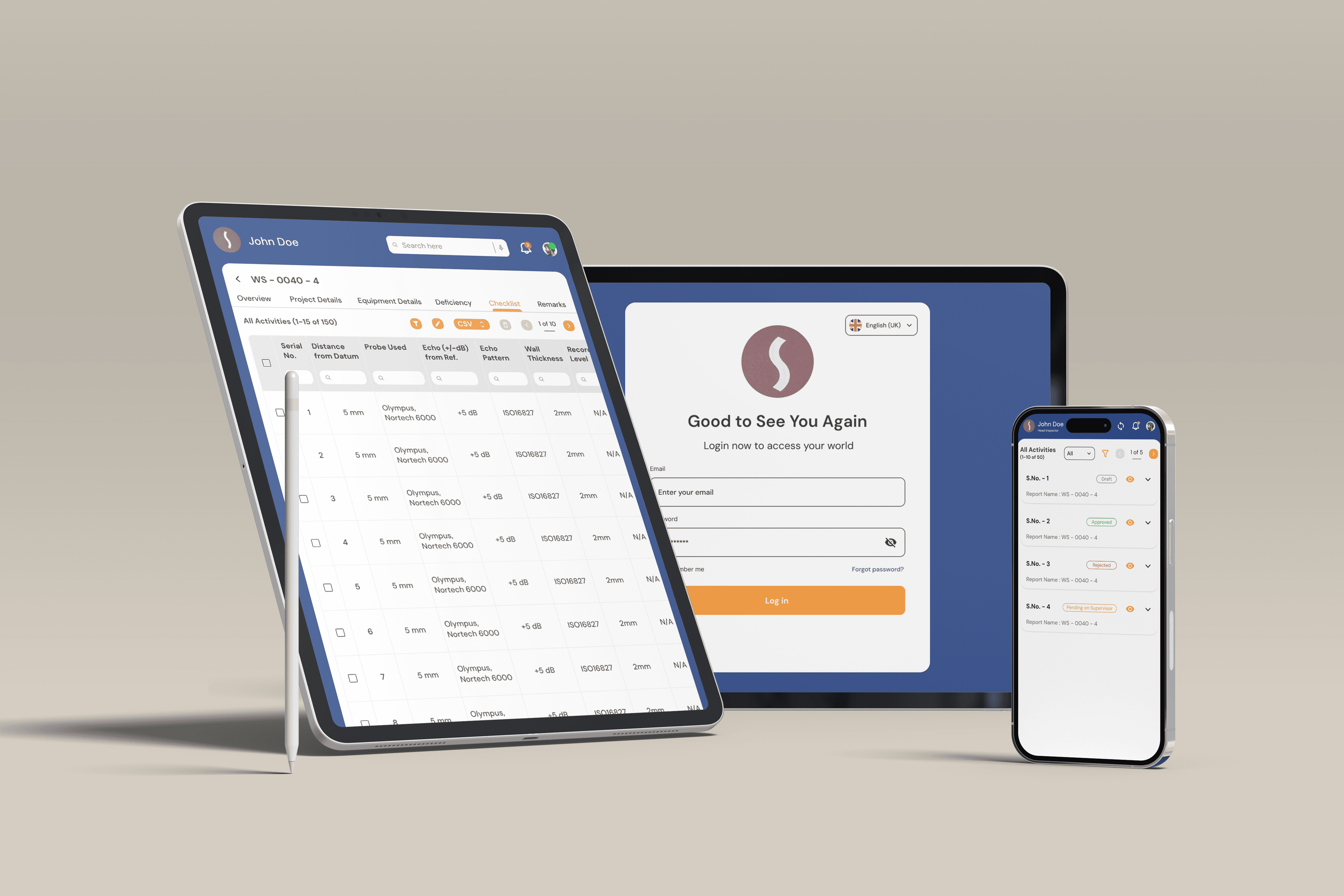

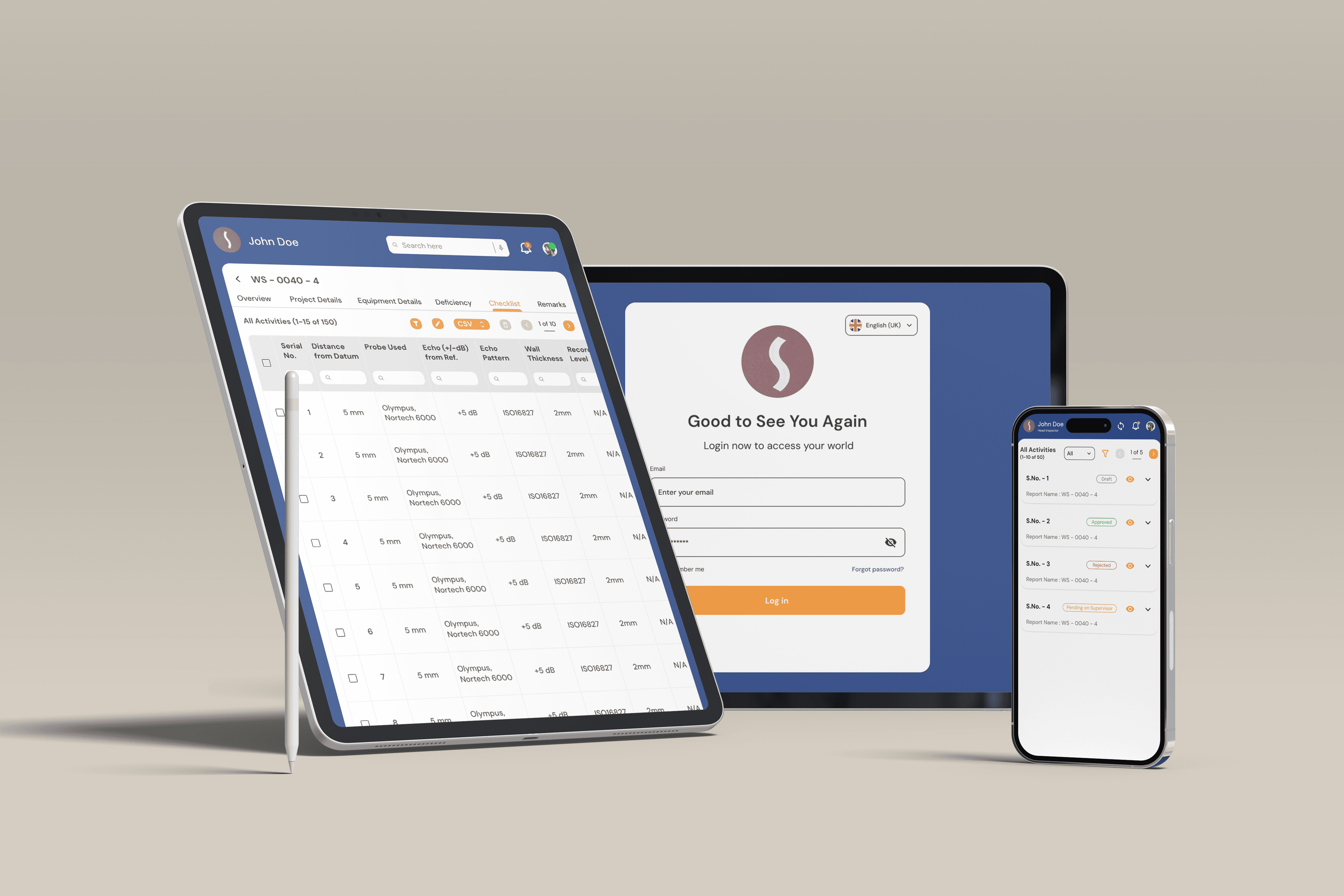

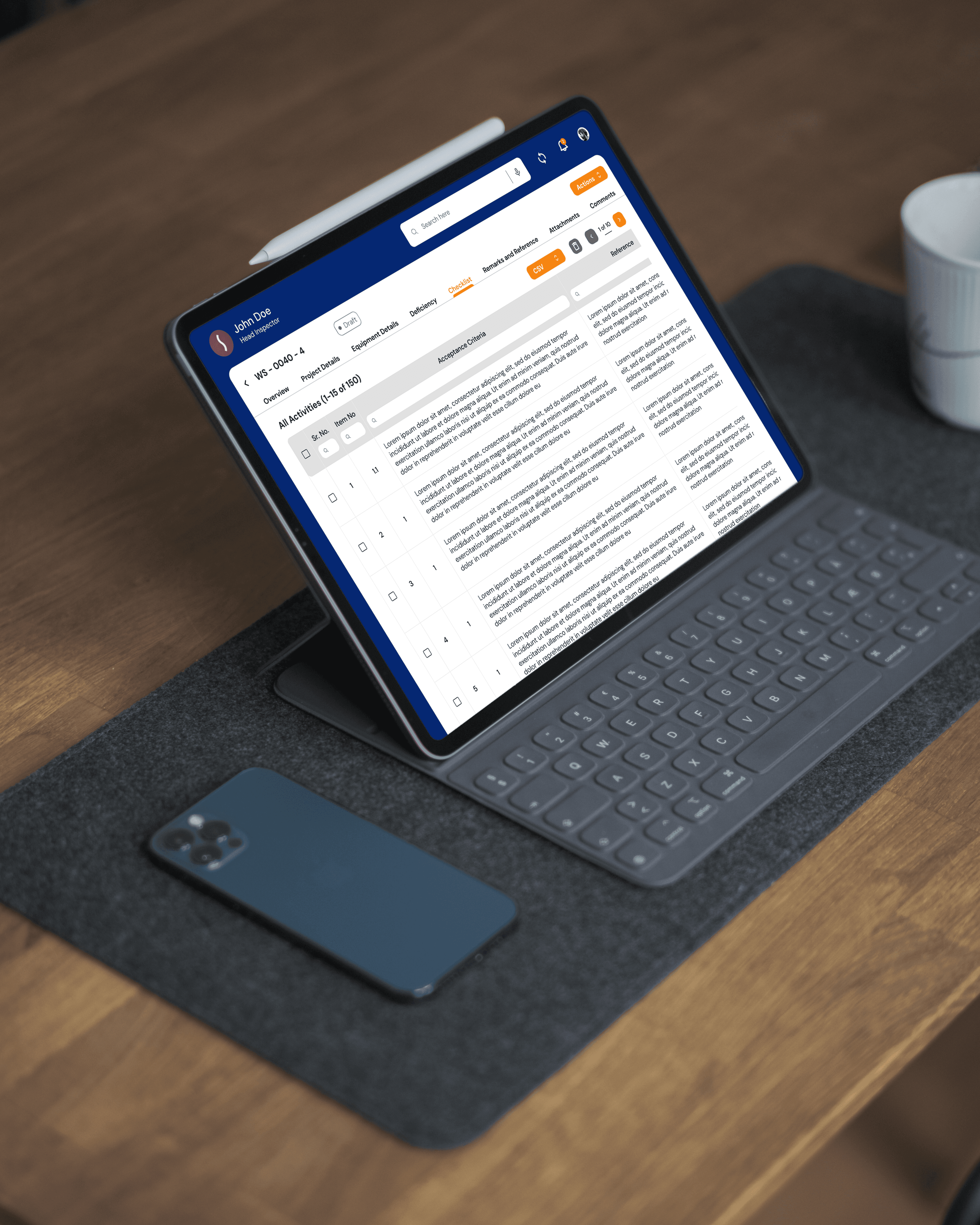

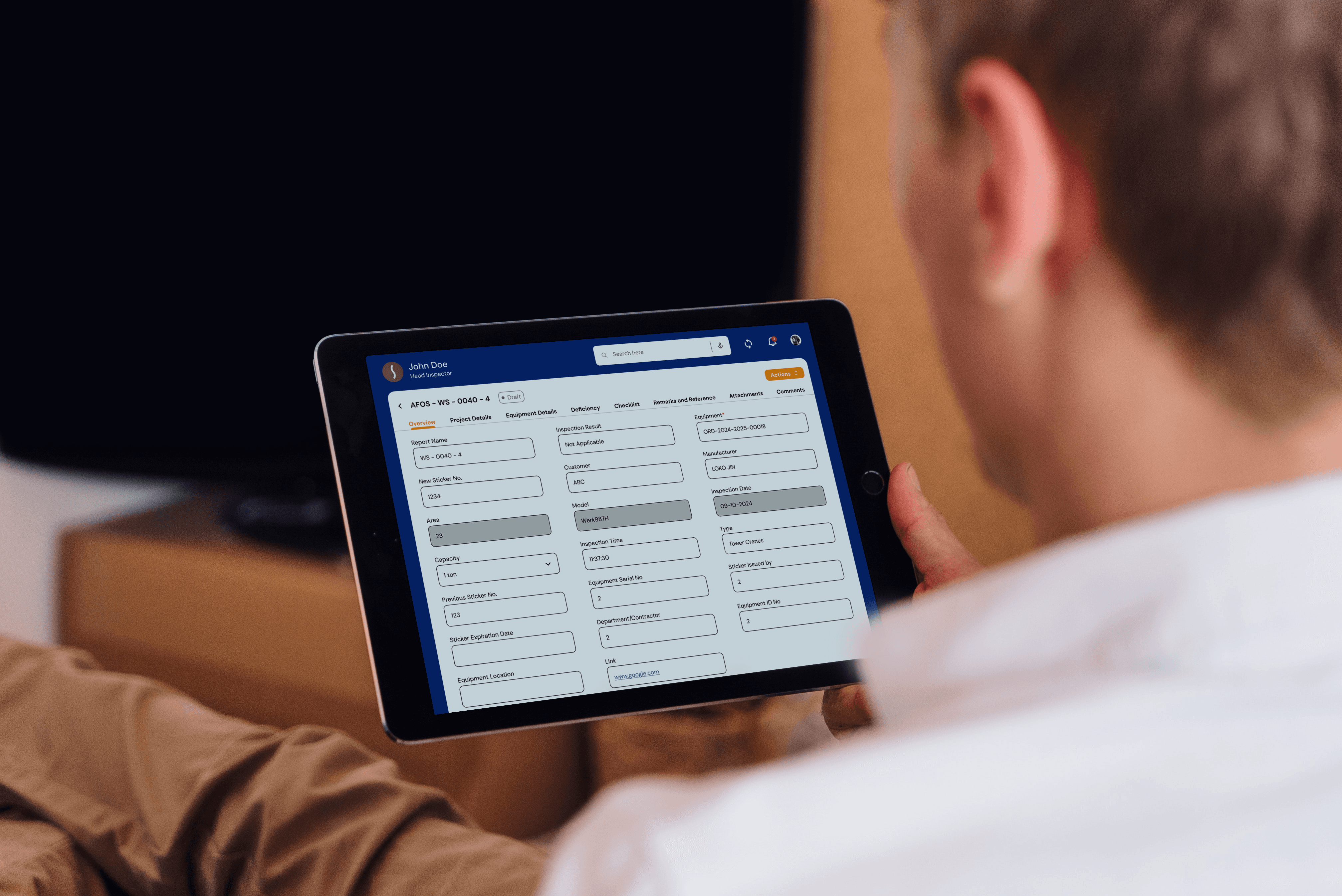

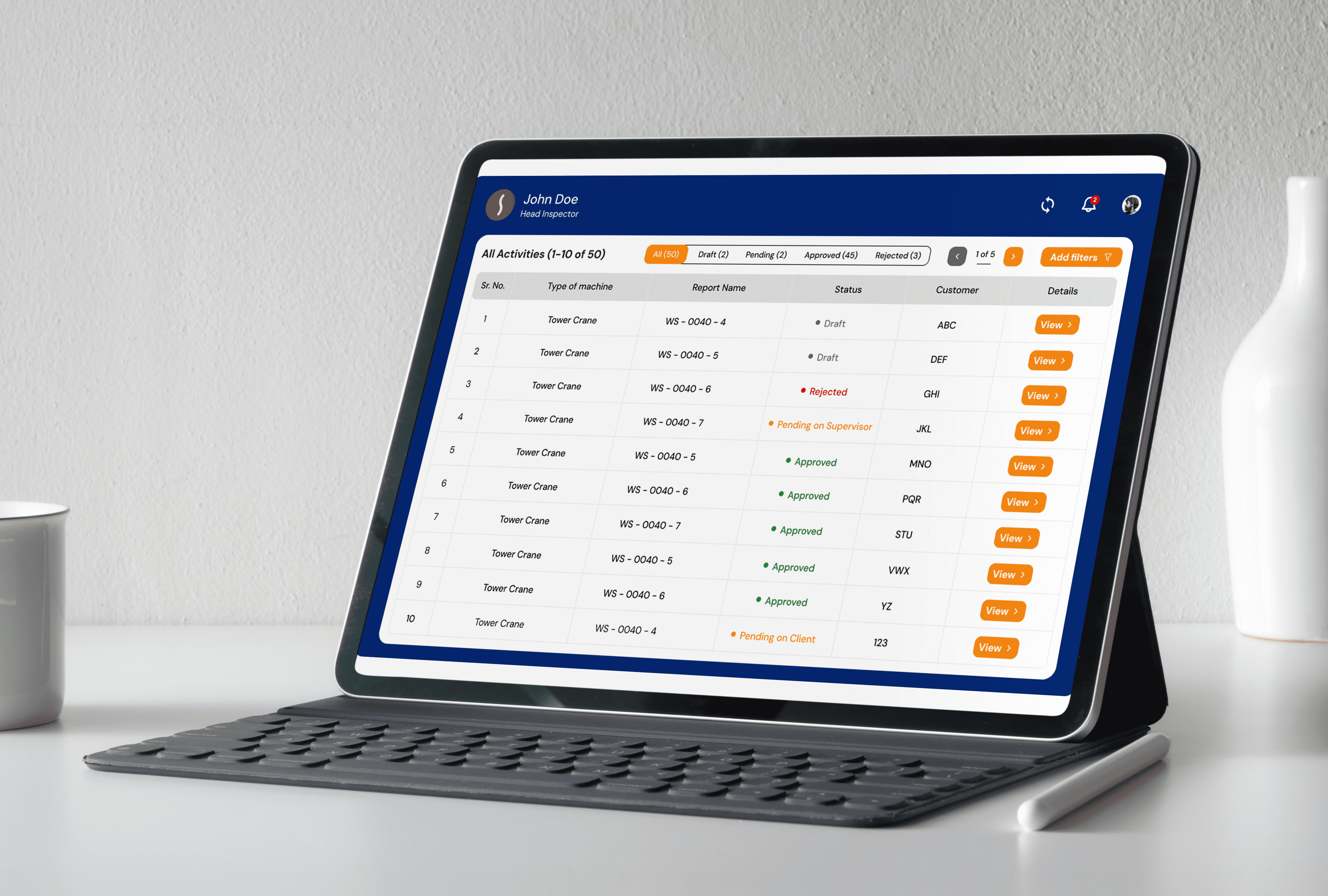

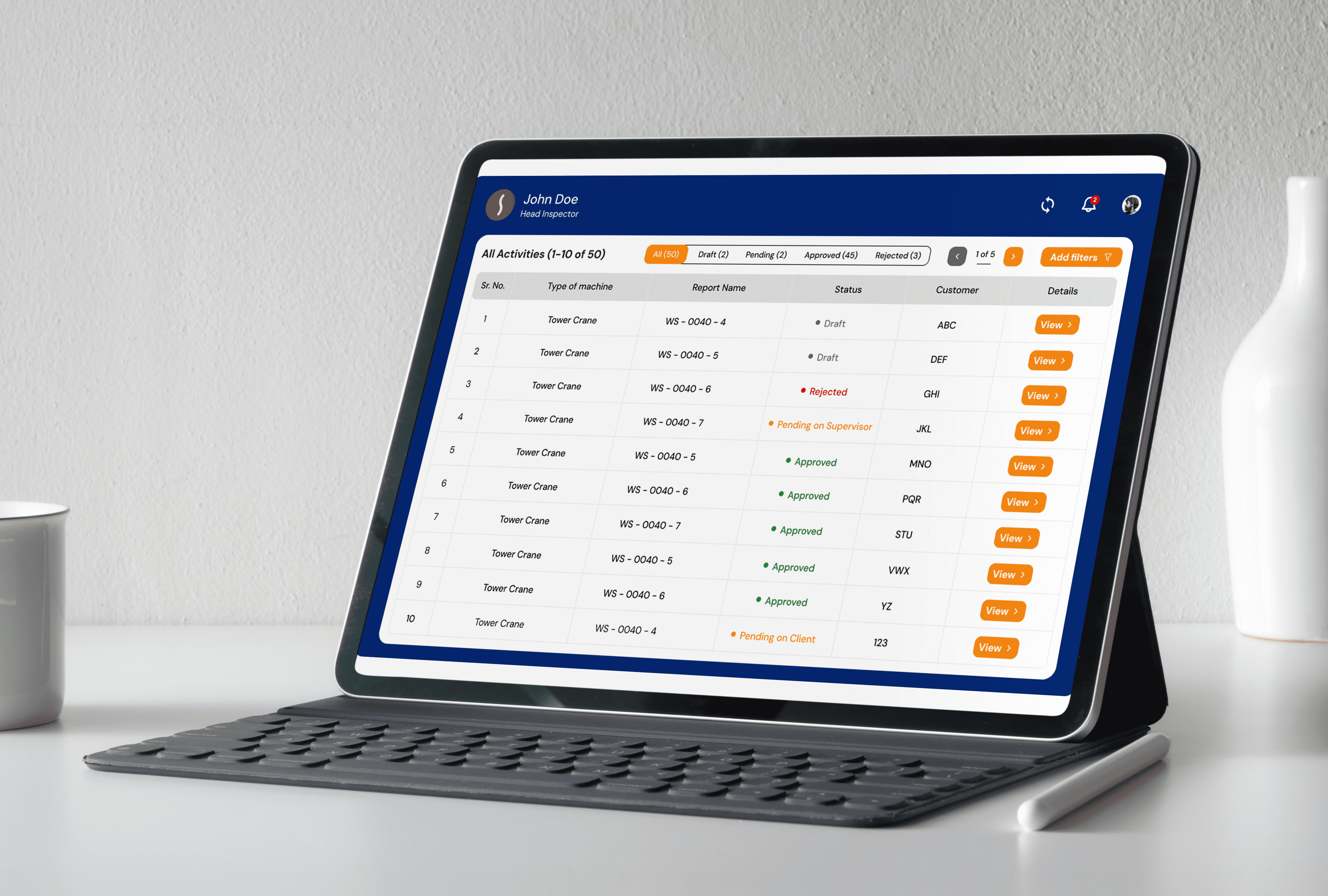

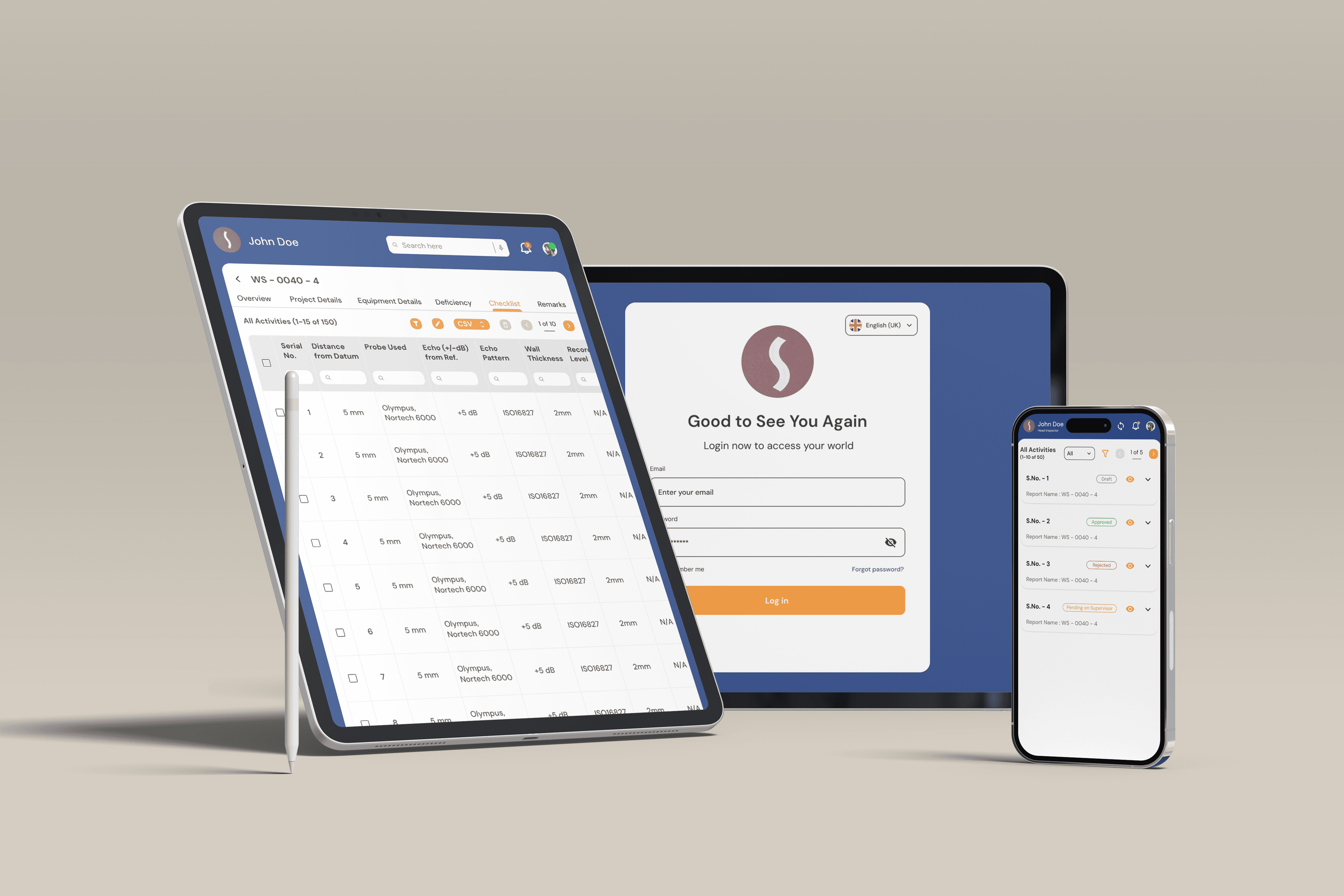

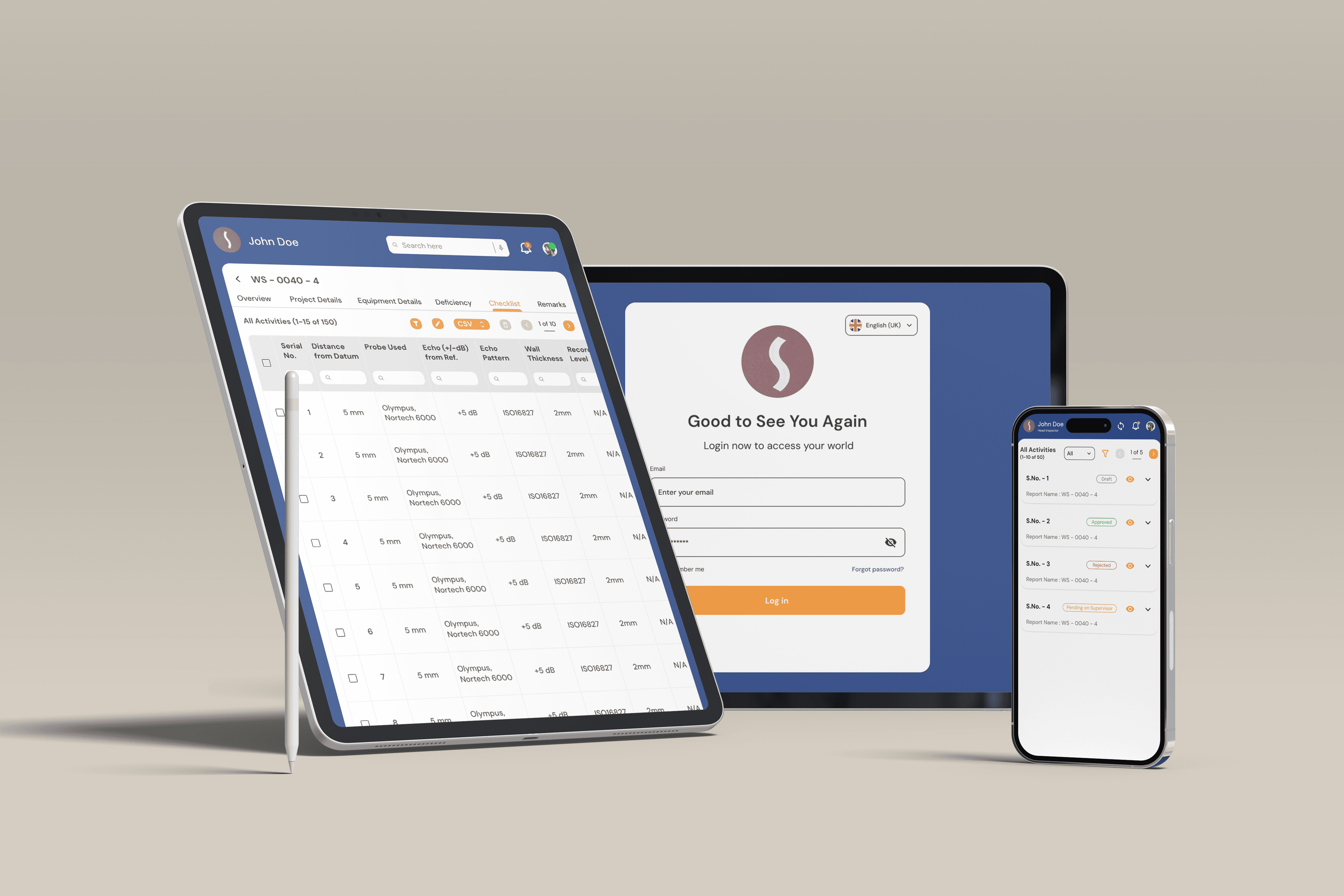

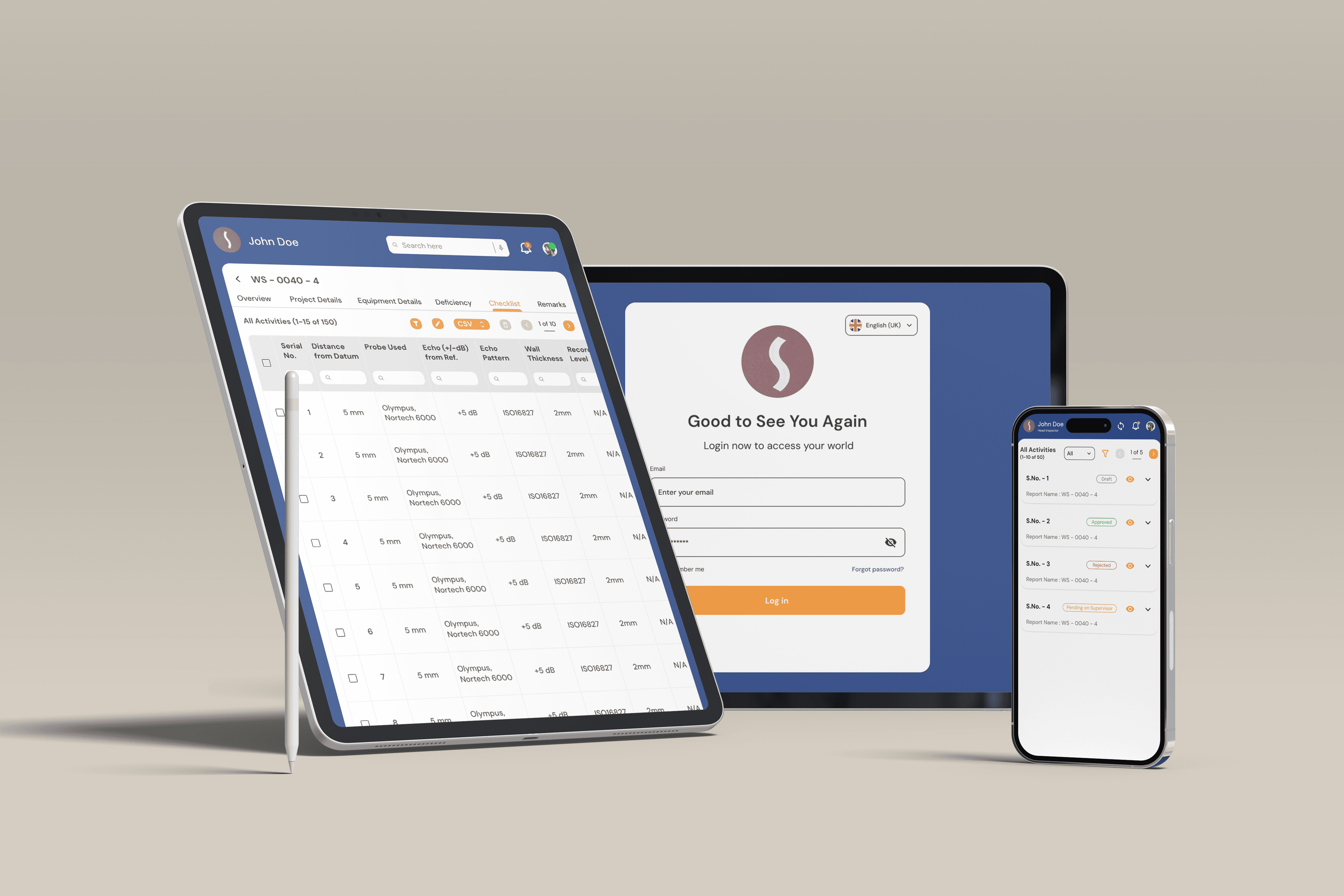

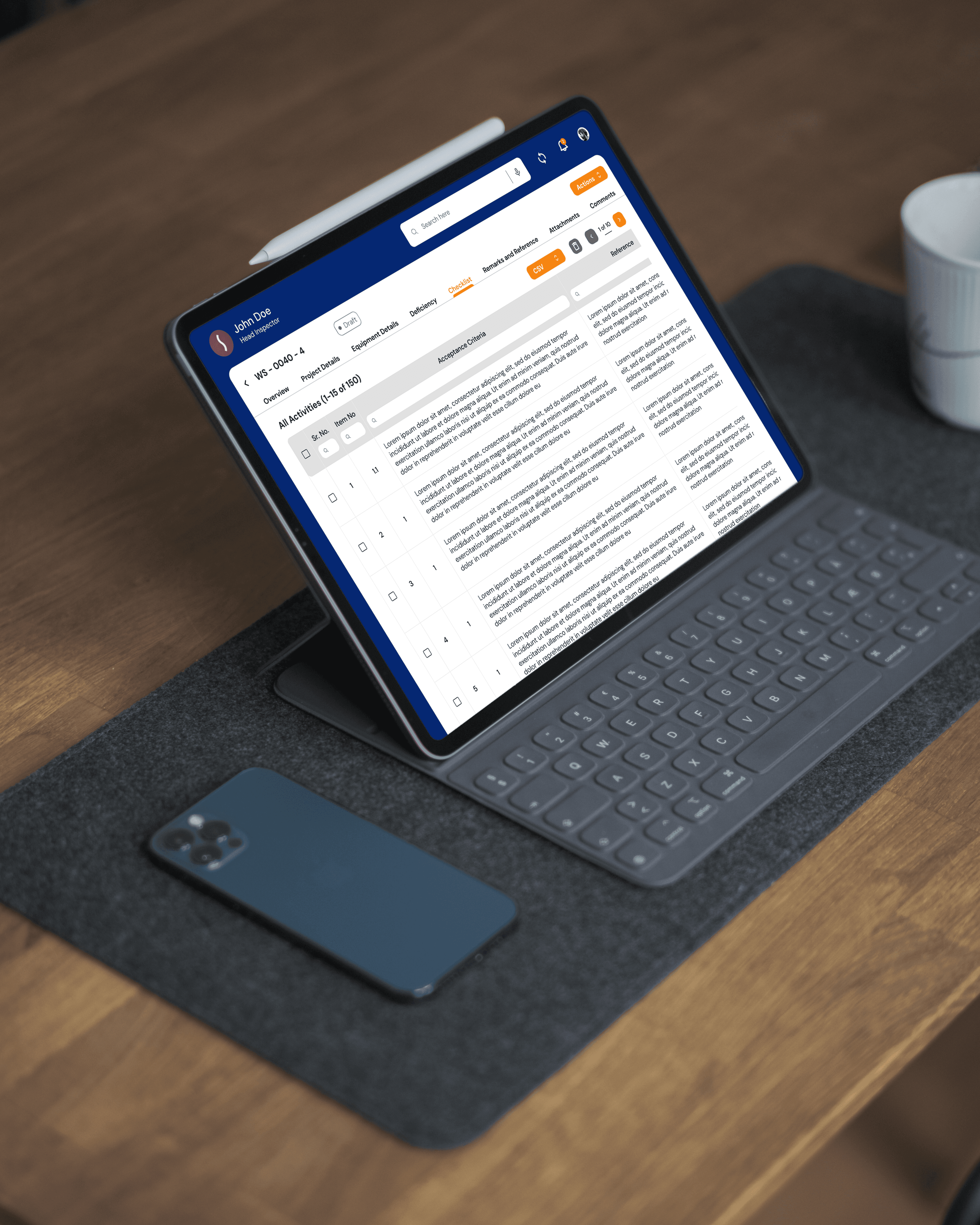

I designed a tablet and mobile inspection platform that enabled inspectors to log inspection results, attach photos, and generate reports directly from the site. The UI was optimized for quick data entry, even with gloves on, and supported offline functionality for remote locations. Real-time sync ensured that supervisors received inspection updates instantly, improving transparency and decision-making.

Challenge :

The primary challenge was designing an interface suitable for industrial environments — where lighting, connectivity, and working conditions can vary drastically. I created high-contrast, glove-friendly touch targets, and ensured navigation could be completed with minimal taps. Data validation rules were implemented to prevent incomplete or incorrect submissions.

Impact :

Reduced report submission time by 50% compared to manual methods

Increased data accuracy by 40% through real-time validation

Improved inspection throughput, allowing inspectors to handle 25% more jobs daily

Achieved near-100% user adoption within the first month of rollout

More Projects

Design Strategy

Digitizing Field Inspections for Greater Accuracy and Speed

Designed a field-ready NDT inspection app that cut reporting time by 50% and improved data accuracy by 40%.

Year :

2025

Industry :

NDT-Tech

Project Duration :

10 weeks

Problem :

On-site NDT (Non-Destructive Testing) inspectors were relying on manual reporting methods — paper checklists, spreadsheets, and phone calls — to record and submit inspection data. This not only delayed reporting but also increased the risk of human error, missing information, and miscommunication between field teams and supervisors.

Solution :

I designed a tablet and mobile inspection platform that enabled inspectors to log inspection results, attach photos, and generate reports directly from the site. The UI was optimized for quick data entry, even with gloves on, and supported offline functionality for remote locations. Real-time sync ensured that supervisors received inspection updates instantly, improving transparency and decision-making.

Challenge :

The primary challenge was designing an interface suitable for industrial environments — where lighting, connectivity, and working conditions can vary drastically. I created high-contrast, glove-friendly touch targets, and ensured navigation could be completed with minimal taps. Data validation rules were implemented to prevent incomplete or incorrect submissions.

Impact :

Reduced report submission time by 50% compared to manual methods

Increased data accuracy by 40% through real-time validation

Improved inspection throughput, allowing inspectors to handle 25% more jobs daily

Achieved near-100% user adoption within the first month of rollout

More Projects

Design Strategy

Digitizing Field Inspections for Greater Accuracy and Speed

Designed a field-ready NDT inspection app that cut reporting time by 50% and improved data accuracy by 40%.

Year :

2025

Industry :

NDT-Tech

Project Duration :

10 weeks

Problem :

On-site NDT (Non-Destructive Testing) inspectors were relying on manual reporting methods — paper checklists, spreadsheets, and phone calls — to record and submit inspection data. This not only delayed reporting but also increased the risk of human error, missing information, and miscommunication between field teams and supervisors.

Solution :

I designed a tablet and mobile inspection platform that enabled inspectors to log inspection results, attach photos, and generate reports directly from the site. The UI was optimized for quick data entry, even with gloves on, and supported offline functionality for remote locations. Real-time sync ensured that supervisors received inspection updates instantly, improving transparency and decision-making.

Challenge :

The primary challenge was designing an interface suitable for industrial environments — where lighting, connectivity, and working conditions can vary drastically. I created high-contrast, glove-friendly touch targets, and ensured navigation could be completed with minimal taps. Data validation rules were implemented to prevent incomplete or incorrect submissions.

Impact :

Reduced report submission time by 50% compared to manual methods

Increased data accuracy by 40% through real-time validation

Improved inspection throughput, allowing inspectors to handle 25% more jobs daily

Achieved near-100% user adoption within the first month of rollout